Stop Oversizing Your Off-Grid Inverter (Here’s What Actually Matters)

Updated:

Calculate your total daily energy consumption in watt-hours by listing every appliance you plan to run off-grid, from your refrigerator drawing 150 watts for 8 hours to your laptop charging at 65 watts for 3 hours. Multiply each appliance’s wattage by its daily runtime, then add everything together. This number becomes your foundation for every sizing decision that follows.

Choose an inverter/charger with continuous power rating at least 25% higher than your largest simultaneous load, not your total daily consumption. If you’ll run a well pump drawing 1,200 watts while your fridge cycles on at 150 watts, you need at least 1,700 watts of continuous capacity. The surge rating matters even more—that same well pump might demand 3,600 watts for two seconds during startup, so verify your inverter can handle these peaks without shutting down.

Understand that DC-coupled systems connect solar panels directly to your battery bank through a charge controller, with the inverter/charger drawing from batteries to power your home. AC-coupled systems use a standard grid-tie inverter for solar, with the inverter/charger managing battery charging and converting battery power when needed. DC coupling offers simplicity and efficiency for new installations, while AC coupling excels when you’re adding batteries to an existing grid-tie system or need to combine multiple power sources.

I learned this the hard way during my first cabin setup when I undersized my inverter by focusing only on average loads. My system shut down every time the water pump started until I upgraded to a unit with proper surge capacity. That experience taught me that paper calculations only work when they account for real-world simultaneity and startup demands—something many online calculators conveniently ignore.

What an Off-Grid Inverter/Charger Actually Does (And Why It’s Different)

The Three Jobs Your Inverter/Charger Handles

Your off-grid inverter/charger is essentially three devices rolled into one hardworking box, and understanding each function helps you appreciate why it’s such a valuable piece of equipment.

First up is the inverter function. This is the magic that transforms the DC power stored in your batteries into the AC power that runs your laptop, coffee maker, or power tools. Think of it like a translator converting one language into another. When you’re camping in your RV and want to run your microwave off your battery bank, the inverter side of the unit makes that possible.

Next comes the charger function. When you plug into shore power at a campground or connect a generator during a cloudy week, the charger portion takes that incoming AC power and converts it back to DC to recharge your batteries. I learned this the hard way during my first winter off-grid when my solar panels weren’t getting enough sun. Having a generator and that built-in charger saved the day, keeping my batteries topped up until the weather cleared.

The third job is the automatic transfer switch. This clever feature seamlessly switches between power sources without you lifting a finger. When you plug into shore power, it instantly passes that AC through to your loads while simultaneously charging your batteries. Unplug, and it switches back to inverter mode in milliseconds. For home backup scenarios, this means your refrigerator never skips a beat during a power outage, automatically drawing from your battery system until grid power returns.

Why All-in-One Units Make Sense for Off-Grid

When I first started planning my off-grid system, I wondered whether buying separate components might save money or give me more flexibility. After installing my combined inverter/charger unit three years ago, I can honestly say the all-in-one approach was the right call, especially for DIY enthusiasts.

The biggest advantage is simplicity. Instead of wiring together an inverter, battery charger, and transfer switch as separate boxes, you’re dealing with one device. Fewer connections mean fewer potential failure points and less troubleshooting down the road. I remember standing in my garage looking at all the components I’d initially considered buying separately, realizing the wiring complexity alone would’ve taken me days to figure out.

Cost-wise, combined units typically run 20-30% less than purchasing equivalent separate components. You’re also saving on additional mounting hardware, extra cables, and breakers. For a DIY installation, this matters because you can redirect those savings toward better batteries or more panels.

The real game-changer is space efficiency. My 3000-watt inverter/charger fits in a space about the size of a small suitcase. Separate components would’ve required double the wall space, which matters when you’re working with limited room in a shed, RV, or cabin. Plus, most all-in-one units come pre-programmed with battery profiles, eliminating guesswork during setup.

The Real Numbers: How to Size Your Inverter/Charger Without the Guesswork

Starting with Your Surge Loads (The Peak Power Reality)

Here’s something I learned the hard way during my first off-grid setup: I calculated everything perfectly for continuous power, then watched my system shut down the moment my well pump kicked on. That moment taught me that surge loads are the real boss when sizing your inverter.

Think of surge power like the effort it takes to push a stalled car versus keeping it rolling. Many appliances need a massive burst of energy for just a few seconds during startup, far exceeding what they draw during normal operation. Your refrigerator compressor might run on 150 watts continuously, but it demands 600-900 watts for those first couple seconds. Air conditioners, power tools, well pumps, and anything with a motor are the usual suspects.

So how do you figure out these surge requirements? The simplest method is checking the appliance nameplate or manual, which sometimes lists “starting watts” or “LRA” (locked rotor amps). If you’re comfortable with measurements, an energy monitor like a Kill-A-Watt can capture these spikes in real-time. No specs available? Use the conservative estimate that motor-driven appliances draw 3-5 times their running wattage at startup, while resistive loads like toasters or water heaters have minimal surge.

Here’s the critical part: your inverter must handle these peaks, even if they only last seconds. An undersized inverter will either shut down to protect itself or damage your equipment by limiting available current during startup. I always recommend adding up your highest-demand appliance surges that might occur simultaneously, then selecting an inverter rated at least 25% above that total. Yes, this might mean buying a 3000-watt inverter even though your continuous load only reaches 1500 watts. That overhead isn’t wasteful; it’s insurance against frustrating shutdowns and failed startups.

Your Continuous Load Sweet Spot

Here’s the reality check most off-grid newcomers need: your continuous load isn’t nearly as high as you think it is. I learned this lesson the hard way back when I was sizing my first cabin system. I added up every appliance, panicked at the total, and nearly bought an inverter twice as large as I actually needed.

Let’s break down realistic continuous loads for different scenarios, because this number determines your inverter size more than anything else.

For a modest RV setup, your true continuous load might only be 500-800 watts. That’s your refrigerator running (150W), a few LED lights (30W), phone chargers (20W), and maybe a laptop (60W). Everything running at once. Most RVers I know operate comfortably on 1500-2000 watt inverters, which gives them breathing room without going overboard.

A small cabin typically needs 1000-1500 watts continuous. Picture this: refrigerator, a few lights, water pump cycling occasionally, maybe a TV in the evening. When I calculated my actual usage over a week, I was consistently pulling 800-1200 watts, even though my theoretical maximum was over 3000 watts if I turned on every single thing simultaneously.

Home backup systems vary wildly, but a realistic essential loads panel might draw 2000-3000 watts continuous. That covers your fridge, freezer, some lights, internet router, and critical outlets. Not your air conditioner, not your electric dryer. Those are surge loads you’ll need to plan for differently.

The oversizing trap catches people because they add every wattage rating together without considering what actually runs simultaneously. Your microwave might be 1200 watts, but you’re not running it 24/7. Your coffee maker pulls 800 watts for exactly seven minutes each morning.

Grab a notepad and list what’s genuinely running at the same time during your highest-use period. That’s your real continuous load. Add 20-25% safety margin, and you’ve got your inverter sizing target. It’s almost always smaller than your initial fear-based calculation suggested.

The Charging Side of the Equation

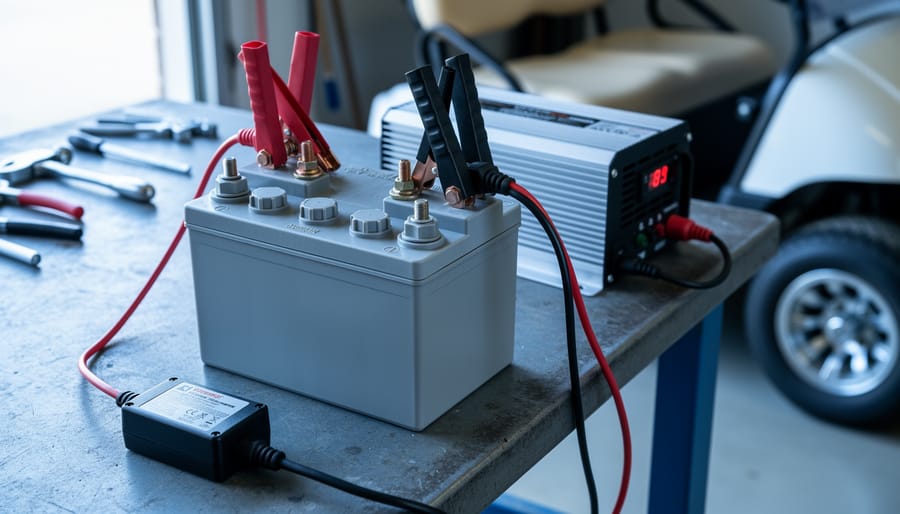

Now let’s talk about the charger side of your inverter/charger, because getting this right makes the difference between waiting days for your batteries to recharge and being back up and running quickly.

The charger amperage you need depends on three main factors: your battery bank size, your generator capacity, and how fast you want those batteries recharged. Think of it like filling a swimming pool—bigger pool needs more flow, and you need to decide if you’re okay with a garden hose or if you need a fire hose.

Here’s a practical rule of thumb I learned the hard way during my first off-grid winter: aim for a charger that can deliver 10-20% of your battery bank’s amp-hour capacity. So if you’ve got a 400Ah battery bank, you’re looking at a 40-80 amp charger. This strikes a nice balance between reasonable recharge times and not overstressing your batteries.

Let me give you a real-world example. Say you’ve depleted your 400Ah battery bank by 50% (that’s 200Ah used). With a 40-amp charger running, you’re looking at roughly 5-6 hours to get back to full, accounting for the slower absorption phase. A 60-amp charger cuts that down to about 3-4 hours. The trade-off? You’ll need a bigger generator to support that higher charging rate.

Speaking of generators, your charger can’t pull more power than your generator can deliver. A 60-amp charger at 12V pulls about 1,000 watts from the AC side, but with inefficiencies, you really need at least 1,500 watts of generator capacity. Always size your generator with some headroom—trust me, running it at maximum capacity constantly isn’t fun for anyone’s ears or the generator’s lifespan.

AC Coupling vs DC Coupling: Which Setup Fits Your System?

DC Coupling: The Traditional Off-Grid Approach

DC coupling represents the most straightforward path into off-grid solar, and honestly, it’s where I recommend most beginners start their journey. The concept is beautifully simple: your solar panels connect to solar charge controllers, which feed power directly into your battery bank using DC electricity. Your inverter then draws from those batteries to create the AC power your household appliances need.

Think of it like a relay race where the baton never changes hands unnecessarily. Solar panels generate DC power, batteries store DC power, and the charge controller simply manages the handoff between them. No conversions happen until the very end when your inverter transforms that stored DC into usable AC electricity.

The efficiency gains here are real and measurable. Because you’re minimizing conversion steps, you lose less energy to heat and transformation losses. I’ve seen well-designed DC-coupled systems achieve overall efficiencies around 85-90%, which translates to real dollars saved on panel requirements.

For most weekend cabin setups, small homesteads, or anyone building their first system under 5kW, DC coupling makes tremendous sense. The components are readily available, troubleshooting is straightforward, and the learning curve is gentle. When something goes wrong, you’re dealing with three main components rather than a complex web of equipment.

The system also excels in reliability. Fewer electronic conversions mean fewer potential failure points. I’ve maintained DC-coupled systems running smoothly for over a decade with nothing more than occasional battery maintenance.

One practical advantage often overlooked: DC coupling allows you to charge batteries even during grid-down scenarios without requiring your inverter to be operational. Your solar panels keep working independently, which provides excellent redundancy for critical applications.

AC Coupling: When You Want More Flexibility

Here’s the thing about AC-coupled systems: they’re like adding extra rooms to your house instead of tearing down walls and rebuilding. When I first learned about AC coupling, I was already running a basic off-grid setup, and the flexibility it offered completely changed my perspective on system expansion.

In an AC-coupled configuration, you’re essentially using standard grid-tie inverters alongside your off-grid inverter/charger. Your solar panels connect to grid-tie inverters that produce AC power, which then feeds into your off-grid system’s AC bus. The off-grid inverter/charger acts as the system manager, controlling everything and keeping your batteries charged when needed.

Why would you choose this approach? Three main reasons stand out. First, it’s perfect for expanding existing systems without replacing equipment. Maybe you started with 2kW of solar but now want 6kW. Instead of scrapping your current setup, you can add AC-coupled panels. Second, you can mix different solar arrays with different orientations. Got panels facing east, west, and south? No problem. Each array gets its own grid-tie inverter. Third, if one inverter fails, your other sources keep running.

The trade-off is complexity. You’re managing multiple devices that need to communicate properly. Your off-grid inverter/charger must be compatible with AC coupling and capable of regulating the grid-tie inverters. During low-load, high-production times, your system needs to prevent overcharging by curtailing the AC-coupled production. Not all off-grid units handle this well.

I added AC coupling to my cabin system last year, and honestly, the installation took longer than expected because I had to configure the communication settings carefully. But now? I can independently upgrade different parts of my system without starting from scratch. For DIYers who value flexibility and plan to grow their systems over time, AC coupling deserves serious consideration despite its added complexity.

Charles’s Take: Which I Use and Why

I’ve installed both AC and DC coupled systems over the years, and honestly, each has earned its place in my toolkit. My off-grid cabin runs DC-coupled, and I absolutely love the simplicity. When I sized that system three years ago, I knew my loads were modest and wouldn’t change much. The direct battery charging during those cloudy mountain days makes a real difference in efficiency, and troubleshooting is straightforward since everything flows through one unit.

My home setup, though, is AC-coupled. Why? Flexibility. When I started, I had a small array, but I knew I’d want to expand. Adding another inverter to my AC-coupled system last spring took me about two hours, and suddenly I had 50% more capacity without rewiring my battery bank or replacing my main inverter.

Here’s my recommendation framework: Go DC-coupled if you’re working with a fixed budget, have a clear understanding of your power needs, and value efficiency over expandability. It’s perfect for small cabins, RVs, or dedicated workshop setups where you know exactly what you’re powering.

Choose AC-coupled when you’re starting small but thinking big, when you have varied power sources you might want to integrate later, or when you’re dealing with an existing system that needs upgrading. The flexibility is worth the slightly lower efficiency, especially if your situation might evolve. I’ve never regretted having expansion options when opportunity knocks.

Matching Your Inverter to Your Battery Bank (The Voltage Question)

When to Go 12V, 24V, or 48V

Choosing the right system voltage comes down to how much power you’re moving through your wires. Think of voltage like water pressure in a pipe—higher voltage lets you push more power through smaller wires, which saves money and space.

For smaller systems under 1,000 watts, 12V works beautifully. This is your sweet spot for RVs, camper vans, and tiny cabins. I remember helping my neighbor Charles set up his teardrop trailer with a 12V system—just 400 watts of solar and a simple inverter/charger. Everything ran smoothly, and the wiring stayed manageable.

Once you’re regularly pulling 1,000 to 3,000 watts, 24V becomes the better choice. The math is straightforward: doubling your voltage cuts your amperage in half, which means you can use thinner, less expensive wire. A typical small cabin with a refrigerator, lights, and occasional power tool use fits perfectly here. Charles upgraded his hunting cabin to 24V when he added a well pump, and his wire costs dropped significantly compared to staying at 12V.

Above 3,000 watts, seriously consider 48V. Larger off-grid homes with multiple appliances, air conditioning, or workshop equipment benefit from the efficiency gains. At 48V, you’re moving serious power without dealing with heavy-gauge copper cables that cost a fortune and require beefier connections.

Wire sizing makes this decision practical, not just theoretical. A 100-amp draw at 12V becomes 50 amps at 24V or just 25 amps at 48V. That difference determines whether you’re running hefty 2/0 cable or manageable 6-gauge wire between your battery bank and inverter.

Start with your peak power needs, add 25 percent for safety margin, and let that number guide your voltage decision.

The Features That Actually Matter (And the Ones That Don’t)

Must-Have Features for Off-Grid Reliability

When I first set up my off-grid system, I learned the hard way that not all inverter-chargers are created equal. The difference between a frustrating experience and reliable power often comes down to a handful of essential features that protect your investment and keep the lights on.

Low-voltage disconnect is your battery’s best friend. This feature automatically cuts power before your batteries drain too deeply, which can permanently damage them. Think of it as a safety net that prevents you from accidentally running your battery bank into the ground during those cloudy weeks when solar production is low.

Programmable charging profiles matter more than you’d think. Different battery types need different charging approaches. Flooded lead-acid batteries require regular equalization charges, while lithium batteries need precise voltage limits. A quality inverter-charger lets you customize these settings, which can double or even triple your battery lifespan. I’ve seen people waste thousands on premature battery replacements simply because their charger settings weren’t optimized.

Generator auto-start capability is a game-changer during extended periods of low sun. Your system can automatically fire up a backup generator when batteries reach a certain level, then shut it down once they’re recharged. No more middle-of-the-night trips to pull a starter cord.

Look for data logging and monitoring capabilities too. Being able to track your system’s performance helps you spot issues early and optimize your energy usage. Temperature compensation adjusts charging based on ambient temperature, preventing overcharging in summer or undercharging in winter.

These features aren’t luxury add-ons. They’re the difference between a system that works with you and one that constantly demands attention.

Nice-to-Have Features Worth Considering

When I first set up my off-grid system, I went with the basics and immediately regretted not spending a bit extra on features that would’ve saved me countless headaches. Remote monitoring tops my wish-list now. Being able to check your battery levels and system performance from your phone means you can catch problems before they become emergencies. Some units even send alerts when something’s amiss, which is worth its weight in gold if you’re not always on-site.

Multiple AC inputs are another game-changer if you have a backup generator or access to shore power occasionally. Instead of manual switching, the inverter automatically prioritizes your power sources, pulling from your batteries first and seamlessly switching to generator or grid power when needed.

Adjustable charge rates give you control over how aggressively your batteries charge, which can extend their lifespan significantly. I learned this the hard way with my first battery bank.

These features typically add 200 to 500 dollars to your inverter cost, but they justify the expense if you’re managing a system remotely, have multiple power sources, or you’re investing in premium batteries that benefit from gentler charging profiles. For weekend cabin setups with basic needs, you can skip them and save the cash.

Common Sizing Mistakes (And How to Avoid Them)

I’ve seen plenty of sizing mishaps over the years, and honestly, I’ve made a few myself when I was starting out. Let me share what I’ve learned so you can skip the expensive lessons.

The most common mistake? Undersizing. My neighbor Charles installed a 2000-watt inverter for his cabin, thinking it would handle everything. He calculated his TV, laptop, and a few lights—seemed perfect on paper. What he forgot was the well pump. The first time his water tank needed refilling, the inverter immediately shut down from overload. The pump’s startup surge demanded about 3500 watts, way beyond what his system could deliver. He ended up replacing the entire unit within three months, essentially paying twice for the same capability.

Undersizing doesn’t just mean inconvenience. It leads to frequent overload shutdowns, potential damage to the inverter, and something called “thermal cycling” where the unit repeatedly heats up and cools down. This dramatically shortens equipment lifespan. I’ve watched people burn through inverters in two years that should have lasted fifteen, all because they shaved a few hundred dollars off the initial purchase.

But oversizing isn’t the answer either. I consulted with a family who installed a massive 10,000-watt inverter/charger for a tiny weekend retreat that barely used 1000 watts. Their reasoning was “better safe than sorry,” but that safety cost them dearly. Large inverters draw more idle power—sometimes 50-100 watts just sitting there doing nothing. Over a year, that’s wasting significant battery capacity. Plus, they paid nearly triple what they needed to spend upfront.

Oversized systems also run inefficiently at light loads. Most inverters operate best between 20-80 percent of their rated capacity. Running consistently below that sweet spot means you’re converting DC to AC power less efficiently, wasting energy your solar panels worked hard to capture.

So how do you find that practical middle ground? Start with honest load calculations, but add a 25-30 percent buffer for unexpected draws and future expansion. Account for surge requirements—multiply motor-driven appliances by three to estimate startup power. Consider your actual usage patterns, not theoretical maximums.

The sizing sweet spot means your inverter handles daily loads comfortably while accommodating occasional heavy draws without constantly running near its limits. Think of it like buying shoes—you want room to wiggle your toes, but not so much space you’re tripping over yourself. When you calculate carefully and size thoughtfully, your system runs efficiently, lasts longer, and actually serves your needs instead of creating new problems.

Getting your off-grid inverter/charger sizing right doesn’t have to feel like guesswork. The key takeaway here is simple: measure your actual energy use rather than making rough estimates. Track your daily power consumption for at least a week, note those occasional high-draw appliances, and add a reasonable safety margin of 20-30% for peace of mind.

I remember when I first started helping my neighbor Charles with his cabin setup. He initially thought he needed a massive 6000W system because that’s what the forums recommended. After actually measuring his loads for a few days, we discovered his real needs topped out around 2500W. He saved thousands by right-sizing his equipment and used that money for better batteries instead.

Whether you choose AC or DC coupling depends on your specific situation. If you’re expanding an existing grid-tied system, AC coupling makes sense. Starting fresh? DC coupling typically offers better efficiency and simplicity.

Don’t forget to check out Spheral Solar’s sizing calculators. These interactive tools take the guesswork out of the math and help you visualize different scenarios without pulling out a spreadsheet. They’re particularly handy when you’re comparing equipment options.

We’d love to hear how your sizing journey goes. Join our community forum and share what worked for you, what surprised you, or where you got stuck. Your real-world experience helps everyone learn and build better systems together.