DIY Solar Generator – Complete Guide With Diagrams

Updated:

Building a weatherproof DIY solar generator involves mounting and wiring a battery, charge controller, inverter, trickle charger, and fusing inside a weatherproof case.

Then all the relevant input and output sockets are wired and mounted on the outside of the case where they are easily accessible.

What Exactly Are Solar Powered Generators?

A lot of folks may be a little confused by the term solar generator. They may associate “generator” with the noisy, gas-powered lump that sits and clatters away in the background in the campsite. A necessary evil to be tolerated in the quest for AC power on site.

And this is where the solar generator really shines. Often referred to as a solar power station or solar energy station, a solar generator is essentially a full-functioned solar power grid in a suitcase.

With a twist, though, as you can recharge their batteries with mains power, car alternator feeds in addition to the obvious solar panel inputs.

They are quiet, portable, and, if it’s big enough, a solar power generator can run everything you’d use with a gas generator. In addition, if they don’t guzzle gas or propane, a point that makes them very attractive is true power outages, and emergency, or disaster relief power sources. And all that from free, abundant solar energy.

What You Will Need for Your DIY Solar Generator Kit

Here are all the necessary parts for your solar generator kit:

DIY Solar Generator Parts

- Wheeled case

- 3000/6000-watt inverter

- 100 watts solar panel

- MPPT 40 Amp Charge Controller

- Battery plus Universal Battery Hold Down

- Battery Maintainer

- 15 Amp AC Port Plug

- 20Amp GFCI Outlet plus Hubbell-Bell Single-Gang Flip Cover

- 150 Amp Circuit Breaker

- Hopkins 6 Pole Round Vehicle Connector plus Tow Ready 6-Way Flat Pin Connector

- 12 Volt 2-way Power Outlet with switch and gauge

- 175 amp Anderson Plug Mounting Kit plus 175 Amp Connecteur 600 V Plug Battery Connector

- LED Illuminated 6-way Automotive Blade Fuse, Holder

- 100 Amp Mini BusBar

Consumables to Make Your Own Solar Generator

- Self-adhesive zip tie mounts

- Silicone Gasket Maker

- Washer & Bolt Assortment

- Standard Fuse Assortment

- Rubber cable grommet set

- Crimp terminal set

- O ring kit

- Gauge primary wire

- Gauge Primary Wire

- Grounded Power Cable

- Battery cable sets

- Zip ties

Tools to Build Your Solar Generator Kit

- Automatic Wire Stripper with Cutter

- Ratcheting terminal crimper

- Corded power or battery drill

- Drill bit selection

- Tool with cylinder grinding bit (optional)

- Reciprocating saw (optional but great for the cut-outs)

- Jigsaw with blades

- Hole saw set

- Round and flat files

- Heavy-duty wire cutter

Not all these items are critical when you build your own solar generator. For the most part, though, they make great additions to the DIY enthusiast’s arsenal and are well worth the investment.

Let’s look at what commercial and DIY solar generators consist of.

What Is Inside the DIY Solar Generator Case?

Batteries

At the heart of any commercial solar generator is one or more batteries. The batteries used in solar generators are typically gel or glass mat marine types. Flooded batteries are not suitable because of the risk of leakage when solar generators are used in different orientations.

In the case of DIY solar generators, builders can opt to construct a custom battery using individual LiPo cells or buy an off-the-shelf battery. The bought battery option is best when you build your own DIY portable solar generator.

Ensuring that the chosen batteries, whether off-the-shelf or custom-built with LiPo cells, provide sufficient capacity to store and supply the necessary power for optimal generator performance.

Solar Charge Controller

As with any permanent solar installation, solar generators’ battery charging is marshaled by a charge controller. Builders may use either PWM or MPPT controllers, and the type and sizing of the controller depend on the project specifics.

These will include the physical space in the enclosure, the battery size, and the solar charging inputs’ types and capacities.

DC to AC Inverter

A solar generator inverter will take the battery’s DC (direct current) output and turn it into AC (alternating current), similar to the power from a home wall socket.

Again, the specifics of the solar power generation project will determine which inverter it chooses. Many folks advocate pure sine wave inverters for solar generators, but they are not strictly necessary.

Ventilation Fans and Controller

The most common way for DIY solar generator builders to ventilate and cool the equipment is to use computer-style fans mounted on the sides of the box.

Solar generators run hot, but auxiliary fans are not necessary when your inverter has good ventilation.

Electrical Protection

A well-built DIY solar generator would include circuit breakers or re-set fuses to protect the user and the components from over-current and short-circuit situations.

For the most part, solar generators utilize components that include comprehensive default protection.

Diagnostic and Programming Modules

These modules display the specifics of the solar generator system, including battery state, charge rates, current draw, and component temperatures.

DC to DC Buck Converter

A Buck converter is essentially a step-down transformer that takes a 48-volt DC input and converts it to 12 volts. A Buck converter is a must-have if your DIY portable solar generator build uses a 24 or 48-volt battery.

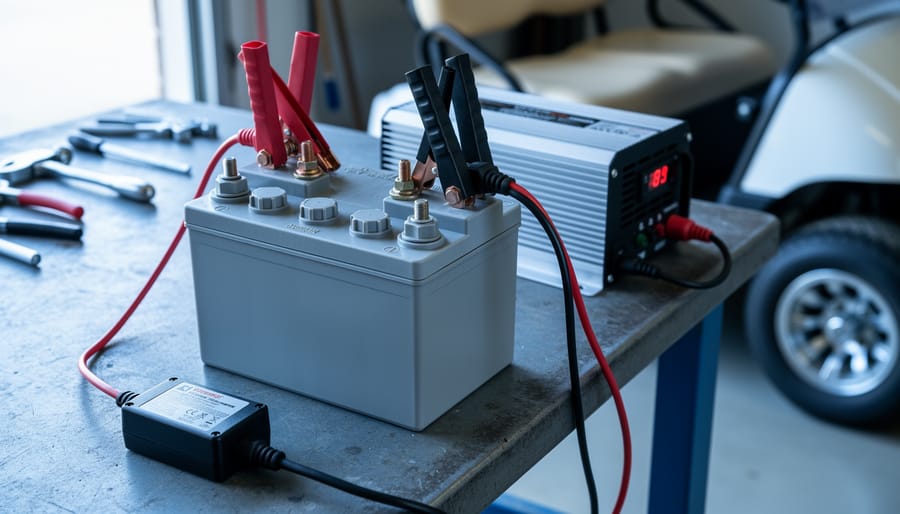

Battery Maintainer

This kit is an AC trickle charger unit that will allow you to charge your DIY solar generator battery from a mains wall outlet while the generator is idle or in storage.

Input Ports, Outlets, and Switching

This is one of the areas where a DIY solar generator trumps store-bought models. You get to decide which sockets and outlets you’ll need and include items you may not find on the Walmart models.

That said, typical outlet layouts on solar generators would include high-voltage AC outlets, low-voltage cigarette lighter-type outlets, USB ports, and high-load Anderson quick-connect type sockets.

Input ports are generally MC 4 solar panel sockets and appropriate inlets for any external power sources you would like to include. Switches typically include a system on/off switch, switches for specific outlets, and switching for accessories.

Accessories

One of the more commonly included accessories in DIY solar generators builds work lights. These are usually LED types that make great practical additions to solar generators.

What Is Outside the Solar Generator Box?

Solar Panels and Cables

The final components of a DIY solar generator build and the only ones not enclosed in the box are the solar panels, cables, and any other link or extension cables. Consider the generator’s specifications to determine the appropriate solar panel size and type. These can range from conventional rigid panels to flexible or folding panel sets.

If you plan to use other non-solar external AC or DC power sources to charge your solar generator batteries, you will have to carry appropriate link or extension cables with suitable plugs or connectors.

Now that we have an overview of the main components involved, let us walk you through the construction of a simple yet very functional and powerful DIY solar generator.

Now, on to our DIY solar generator step-by-step build guide.

Step-by-Step Guide for a 3,000-Watt DIY Solar Power Generator

The core concept behind this DIY solar generator design was high output capacity and good levels of convenience without excess bulk.

We wanted to build a DIY solar generator to bridge the gap between dinky overnight suitcase models and humongous industrial-strength types. Something that would have the power to be efficient in most applications while still being easy to load and run.

So, before we dive into this DIY solar generator build guide, let’s consider our choice of the major components and give you some idea of why we chose them.

The Pelican 1620 Protector Case

We chose the 1620 case because of its rugged MilSpec construction, spacious interior, luggage-style wheels, and pull-out handle. It is a common choice for DIY projects that call for a ton of space, robust construction, and an excellent weatherproof rating perfect for solar generators.

The Optima D34M Battery

The Optima Blue top D34M is a heavy-duty dry glass mat marine deep cycle battery. We chose this particular type over lithium-ion batteries because of its outstanding performance and true deep-cycle specifications. You can mount them in any orientation without leaking or suffering damage, or performance degradation is an important consideration for solar generators.

The Krieger 3000/6000-Watt Inverter

With the Krieger 3,000-watt continuous and 6,000-watt surge rating, this inverter has enough muscle to run most appliances and equipment comfortably. Although this is a modified sine wave rather than a pure sine wave inverter, it is perfect for this application.

A pure sine wave inverter is necessary when running susceptible electronic equipment, but not for a portable solar generator.

The BougeRV MPPT 40 Amp Charge Controller

We opted for the BougeRV 40 A MPPT charge controller for several reasons. One of the concepts behind this design was to build a portable DIY solar generator that would deliver the best performance under all conditions. This operation flexibility is crucial when you build your own DIY solar generator.

MPPT controllers can process far higher solar panel voltage inputs than PWM types. This would allow you to connect several solar panels in series, giving you far superior charging numbers for longer periods during the day. This would also greatly boost shadow areas and overcast or cloudy weather where solar power is minimized.

The Renogy 100-Watt, 12-Volt Solar Panel

Most solar panels designed to be “portable” will give you 30 watts output maximum. As a matter of fact, many won’t do much more than 10. Throw in cloudy weather, shaded locations, and short days, and you might as well abandon solar power and buy a gas generator.

The Renogy 100 watt panel is less portable but not terminally so, and it packs a serious punch. It is also a good choice for pairing up with additional solar panels as the DIY solar generator would comfortably handle up to 100-volt solar input.

When you build your own DIY solar generator, panel expansion is an option you must keep open.

Mounting the DIY Solar Generator Components

We’ll use a suggested layout for all the DIY solar generator components that work well throughout this build guide. That said, it is just a guide, and you can customize your own DIY solar generator according to your build needs or specific equipment.

NOTE: All diagrams used in this guide depict the DIY solar generator case and components relatively accurately in terms of dimension. You will, however, have to check the placement carefully when doing any component mounting.

Internal Components

Here is a schematic representation of the 1620 case’s internal dimensions and suggested internal component layout for the DIY solar generator.

Mounting the Battery

The battery is located at the bottom, wheel end of the case. This will lower the heaviest component over the wheels to give the best support for the battery and balance to the DIY solar generator build.

The battery is being put in the right-hand corner, hard up against the sides of the case. This location offers stability and a secure mount but does have one issue with the wheel arches. To get the battery mounted securely, you’ll have to create a standoff that will lift the battery above these arches.

The easiest way to do this is to use hot melt glue to fix two short 2″ x 2″ strips of wood on the bottom of the solar generator case, as indicated below.

NOTE: While mounting the battery, keep the supplied boots over the battery terminals to prevent short circuits.

Once the glue has set, you can place the battery in position, making sure it’s snug against the sides of the case. Now take the universal battery hold-down clamp and adjust it to firmly grip the top and bottom of the battery between the wood strips. Insert one of the supplied mounting bolts through the top hole of the clamp and mark its position on the wall of the solar generator case.

Now you can remove the battery and drill an appropriately sized hole through the case wall at your mark. Use the set clamp to index the top hole so you can mark the bottom hole. Drill the bottom hole and replace the battery on the standoffs.

You can then put the clamp in place, push both mounting bolts through the holes, and install the nuts outside the case. These bolts are generally a lot longer than is necessary, and you’ll have to trim them. Mark the bolts with a little extra length beyond the nuts and disassemble the clamp. Cut the excess off the bolts, smooth the cut edges with a file or sandpaper, and reassemble the clamp on the battery.

NOTE: When assembling the battery clamp, choose two O rings from your kit that fit snuggly over the bolts and push them up against the outside of the case. Now insert the washers and nuts on each bolt and tighten them up. This will sandwich the O ring between the washer and the case wall, forming a watertight seal.

The completed battery mount will look like this.

Mounting the Inverter

The inverter mounts on the main carry handle or front side of the solar generator case with the cable terminals towards the battery.

Setting up

Attaching the main battery cables before you mount the inverter is a good idea. The placement of the inverter puts the positive lead towards the top and the negative lead at the bottom.

To keep the manual on-board on/off switch clear, you may want to mount the positive inverter cable horizontally. You can mount the negative cable vertically to exit over the top of the inverter. Use the supplied boots when mounting your cables and make sure the connections are clean and tight.

Mounting

Place the inverter in position at least two inches off the floor of the case to give the inverter as much free space for cooling airflow. To this end, also make sure never to obstruct the fans on the rear of the inverter.

Now mark the two bottom mounting holes, ensuring they will not interfere with the handle. Drill the holes and push two #10 machine screws through the case wall from the outside. Use the same O ring and washer arrangement outside the case as you did with the battery mounts to ensure weatherproofing. Place the inverter over the machine screws and insert the nuts and snug them up.

You can now mark the top two holes and repeat the process. Once the inverter is secure, you can tighten all the mounting nuts to lock it in place.

The result will look like this.

Mounting the Charge Controller and Display

Setting up

As was the case with the inverter, it makes life easier if you pre-wire the solar charger before installation.

Cut two 24-inch pieces each of the red and black 14 gauge wire. Strip the insulation back around ½ inch on one end of each lead. Insert the two pairs of leads into the connections marked solar panels and battery on the charge controller. Ensure to connect the red wires to the positive terminals (+) and the black wires to the negative terminals (-).

Mounting

The solar charger mounts centrally at the top of the pull-out handle side of the case. The display mounts close to it at the top of the lid hinge side.

Hold the controller in place on the case wall around ¾ inch from the top edge and mark the 4 mounting holes. Drill the holes through the wall and push appropriately sized machine screws through the wall from the outside. Using the sandwiched O ring and washer method, fasten the controller securely in place.

Repeat the process with the solar charger display’s two mounting holes on the adjacent hinge sidewall. Before drilling these holes, ensure they don’t interfere with any of the case fittings.

The result will look similar to this.

Mounting the Battery Maintainer

The last of our main hard-mounted internal components is the Schumacher battery maintainer. This component mounts next to the controller display. It is also positioned towards the top of the case wall.

The battery maintainer mounts with two bolts, and the mounting process is the same as the rest of the components. Once you are happy with the placement of the maintainer, mark and drill the two mounting holes and fasten the unit to the case with machine screws, this should be what you end up with.

The only internal components left to mount are the fuse box and the negative bus bar. These are not hard mounted but rather hot melt glued into place. We’ll discuss their locations during the wiring of the DIY solar generator.

Mounting the External Components

Mounting the external components of this DIY solar generator is more challenging than the internal parts. For the most part, they will require you to either cut large holes or make cut-outs in the case walls which can be tricky.

This is where a comprehensive hole saw set, and the Dremel tool will be invaluable. Here is a quick tip for jigsaw cutting regularly shaped holes. You can also use a hand fretsaw or even a hacksaw blade to make cut-outs similarly.

Here are schematic layouts of the positions of all the external components for reference.

NOTE: With most flush surface mount components, the device has a flange and cut-out footprint. The cut-out footprint refers to the outline of the component that physically goes through the case wall. Here is an example as a reference for all the external surface mount components in this build.

NB: For each of the components we will mount going forward, you’ll be marking the case for the cut-out dimensions.

Mounting the Inverter Remote On/off Switch

This switch is labeled as B in the top-side component diagram above and is located on the left-hand side of the handle side of the case. To mount the switch, measure the cut-out profile and mark it on the case in the position indicated. Using a jigsaw or hand saw, cut out the marked outline and check that the switch fits through the hole snuggly but freely.

Smooth the cut edges with a file or sandpaper and insert the switch cable and body through the hole. With the switch flange firmly against the case wall, mark the four mounting holes. Remove the switch and drill the holes with a drill bit matched to the mounting hardware supplied with the inverter.

You can then run a bead of RTV silicone sealer around the inside of the switch flange and wait around 10 minutes for it to cure. When the sealer has firmed up, you can replace the switch in its cut-out and screw it down firmly. The RJ 11 plug from the switch can then be run underneath the inverter and plugged into the port below the negative terminal.

Mounting the 6-Way Trailer Plug

This plug will be used as an interface for the solar panel inputs and is located above the inverter remote switch. It is marked as A on the layout diagram.

The cut-out profile for this plug is 1 ¼ inches, and this is a standard size in the hole saw kit listed above. Mark the circular cut-out in the correct position and use the hole saw to cut the entrance hole. Use the largest drill bit if you don’t have a hole saw. You have to drill a pilot hole and open it up with a round file or the Dremel tool.

When the hole is complete and cleaned up, push the plug through the hole, hold it firmly in place, and mark the two mounting holes. Then remove the plug and drill the holes. Before mounting the plug, you’ll need to make the connections first.

Locate the red and black 14 gauge wires you connected to the solar panel terminals on the charge controller. Make certain you have the correct ones. Pull the wires through the cut-out for the trailer plug and trim them to include approximately 6 inches of slack. Use the wire stripper to cut the insulation back and connect it to the vehicle plug.

The positive (red) wire is connected to the center pin on the plug for this particular component. The negative (black) wire is connected to the ground pin. Once the wires are connected to the plug, you can apply an RTV sealer to the inside of the flange and let it cure. Then push the plug back through the cut-out and use machine screws to secure it in place.

Mounting the 12 Volt Multi-Port Pod

This component will supply the generators with low-current 12-volt outputs. It consists of a dual 5-volt USB port with an LED voltage meter, a 12-volt cigarette lighter-type outlet, and an on/off switch. This component is marked C on the layout diagram and mounts in the middle of the wall low down close to the handle cut-away.

There are three cut-outs for this component. Luckily they are all 1 1/8 inches in diameter, which is also a standard hole saw size. The best way to mark the positions of the holes is to remove all the outlet switches from the flange and use the flange as a template to mark the holes. Alternatively, you could simply cut the holes through the flange openings with the hole saw.

Now, reassemble the pod and push the outlet collars through the holes so you can mark the four mounting holes on the flange. Drill the holes and run the RTV sealer around the inside of the flange. When the sealer has cured, put the pod in place, screw the collar nuts back onto the pod from the inside, and tighten the assembly up using the supplied screws.

Mounting the 15 Amp AC Port Plug

The port plug is used to bring 120-volt AC power into the generator to run the battery maintainer. It is marked as D on the layout diagram and is the last component on the front side of the case.

The cut-out profile for the port plug is 1 7/8 inches which is not a common hole saw size. However, the 2-inch hole saw is only 1/8 or 0.125 inches oversized. The port plug has a sturdy, generous flange and three mounting holes, so the 2-inch saw would work just fine.

Place the glug against the case wall in the correct position and trace around the cut-out. Use the hole saw to cut out the hole and smooth off all rough edges. Feed the integral cable through the hole and hold the plug firmly against the case to mark the three mounting holes.

Remove the plug, run a generous bead of silicone sealer around the inside of the flange, and let it cure. Then reinsert the plug and use machine screws to secure it in place. At this point, you can plug the battery maintainer into the port plug socket.

Mounting the 20 Amp GFCI Outlets and Cover

We now swing around to the main carry handle side of the case to mount our last two external components. The 20 Amp GFCI socket is labeled as B on the main carry handle side components diagram. This is the generator’s main AC power outlet.

Mounting these components takes a bit of preparation. Before you get going, you will have to file, grind or cut down the two ribs on the case surface as indicated below.

This will give the outlet and cover a smooth, flat surface to mount on to ensure a weatherproof seal. To get this done, assemble the cover and socket, place it in position and mark the cover outline on the case wall. Then cut the ribs down flush with the case wall with a bit of extra room as illustrated for good measure.

This assembly is a two-part affair. The GFCI outlet goes through the case wall while the weatherproof flip cover mounts on the surface of the case. Two bolts then pass through the cover and outlet to secure the entire assembly.

So, the cut-out profile will be the outlet itself which can be marked by holding it up against the case and tracing the socket outline. The placement of the outlet should be in the center of the imaginary rectangle formed where you took the case ribs out. Clip the outlet into the cover temporarily and check that your markings are good.

Now you can cut the hole using a jigsaw or hand saw as described earlier. When you’re done, check the outlet goes through the case snuggly, and remove the burs from the cut line. You can now mark the two mounting holes and drill them to accept # 10 machine screws. You will probably have to open the holes in the outlet bracket and cover because they were designed for slightly smaller fasteners.

Setting Up and Mounting the Outlet

Connecting the inverter extension cable to the outlet is a good idea before you mount it permanently.

To do this, feed the 12 gauge outlet extender cable through the outlet hole. Plug the three-prong plug into the inverter’s AC outlets and check how long the cable should comfortably reach the GFCI outlet. Leave a little extra for safety and cut off the excess along with the 3-way adaptor.

Using a carpet knife, carefully strip the cable’s outer sheath back around 3 inches. Now use the wire stripper to clear a ½ inch of insulation off each of the three leads.

Now connect the pigtail to the outlet using this color coding. The green lead is connected to the green ground terminal, the white to the silver neutral terminal, and the black lead to the brass-colored hot terminal.

Now you can run a good bead of silicone around the inner contact edge of the cover and wait for it to set. When it’s cured, clip the outlet into the cover and run the machine screws through both. Put washers and nuts on the screws and snug the assembly down securely. The last step is re-inserting the pigtail plug into the inverter AC outlet.

Mounting the 175 Amp Quick Connect/Disconnect Socket

The quick connect/disconnect socket is labeled A on the illustration above and is used as a high-current 12-volt DC outlet. This component allows you to jump-start vehicles, use high-load 12-volt equipment, and, most importantly expand your battery bank outside of the case.

The quick-connect socket has no flange and is tricky to mount. The most secure option is probably to use the two integral mounting holes to bolt the plug flat against the case wall. Unlike the GFCI outlet, we’ll use the case ribs to good effect here to give the plug enough standard room to put the dust cover on.

Place the socket in the position indicated and use a scriber to mark the mounting holes, avoiding the ribs. Drill the holes to accept # 10 machine screws and slip the dust cover ring into place around the socket. Push the machine screws through the sockets, mounting holes and insert them through the case wall. Using an O ring, washer, and nut, fasten the socket securely from the inside of the case.

Setting the Plug Up

Now you can grab one set of your 4 gauge battery cables. They will be used to connect the socket to the fuse box. The first step is to cut one of the standard lugs off each cable and strip the insulation back around a ½ inch. This will allow you to crimp the quick-connect socket’s lugs to the battery cables.

These are pretty robust terminals and require a heavy-duty crimper. If you don’t have one, you can use a round punch and hammer to punch an indentation into the lugs. So, insert the stripped end of the battery cable into the quick-connect lug and crimp it in place. Repeat the process with the second cable.

Now insert the lugs into the socket with the snap lip turned towards the top of the socket. As you seat the lug, you’ll hear and feel a distinct click, and the lug will be locked into position. Just make certain you connect the black lead to the negative side of the socket and the red to the positive.

Connecting the Socket

The last step is to drill an access hole in the case and fit a rubber grommet for the cables to pass through. First, choose a grommet from your kit that will allow both cables to pass through with minimal expansion of the grommet diameter. You may have to pass the cables through the grommet one at a time to do this.

When you have found a suitable grommet, select a drill bit that closely matches the diameter of its inner part. Use the bit to drill a single hole approximately 3 inches behind the socket. With the grommet on the cables close to the socket, pass the battery lugs through the hole and pull the cables into the case.

Pull the grommet down to the hole and force the rear flange or shoulder through it when you have the cables in place. This can take some doing, and you may need to use a flat screwdriver to get it pushed through.

When it’s correctly positioned, its rear flange will be inside the case, and its front flange on the outside with the cables firmly gripped in its center. This will protect the cables but won’t be 100 percent waterproof, so apply a dollop of silicone sealer to the entry.

The result will look like this.

Wiring and Testing the DIY Solar Generator

Once all of the components have been mounting, you’ve broken the back of the project as the wiring is a relatively small task. To try and keep this simple, we’ll describe the wiring in 6 steps that follow a logical order.

- Inverter to battery wiring

- Battery to negative bus and fuse box plus DC quick connect socket wiring

- Battery charging circuits

- Low current DC circuit

- GFCI AC outlet wiring

- Inverter remote on/off switch

NOTE: When wiring up the components of your DIY solar generator, always leave enough slack in the individual wires to allow them to be tucked away against the sides and bottom of the case. This doesn’t really apply to the heavy gauge inverter leads, but for the rest, size the wires with a neat final routing in mind.

Inverter to Battery Wiring

The first order of business is to prepare the fuse box (B) and negative bus bar (C), as indicated in the illustration below. To do this, use hot melt glue to securely attach them to the bottom of the case in the positions indicated.

Now run the inverter positive and negative leads into place in front of the battery and put the respective terminals on the correct battery posts. This will give you a good idea of the best layout for the cables so you can establish the position of the positive inline fuse (A).

When you’re happy with the layout, use hot melt glue to mount the inline fuse permanently. Now snug the terminals down lightly with the battery fasteners to keep everything in place.

Negative Bus and Fuse Box Plus Quick Connect Socket Wiring

The next step is to connect positive and negative links (A) from the battery to the fuse box and negative bus bar. You’ll use your second set of 4 gauge battery cables for this. The suggested routing is illustrated below.

Fuse Box and Negative Bus Bar Links

Connect the positive battery link from the positive battery terminal to the master connection on the fuse box. Connect the negative link to the battery and one of the master connection points on the negative bus bar.

NOTE: When the fuse box and negative bus links have been laid out, take them off the battery terminals for the rest of the build. This will keep the entire circuit isolated and prevent any short circuits.

High Current DC Quick Connect/Disconnect Socket Wiring

The first step in this part of the installation is mounting and wiring the 150 amp circuit breaker (B) into the quick connect/disconnect circuit. To do this, you must lay the wiring out as indicated and choose a location for the circuit breaker. Now use hot melt glue to securely mount the circuit breaker onto the bottom of the case.

When the circuit breaker is mounted, you can cut the positive lead to size, strip the insulation, and crimp 2 x 1/8 inch ring connectors onto each end of the lead. Connect the two ends of the positive lead to the master connections on the circuit breaker (B).

Now connect the positive and negative leads from the externally mounted quick-connect socket to the master connection points on the fuse box and negative bus bar as indicated above (C). Now you can tighten the fuse box master connection up securely. Just be careful not to be too enthusiastic and break the plastic frame.

Battery Charging Circuits

The battery charging section of the generator is divided into two sections, namely the solar panel and external AC sections. The illustration below shows the layouts for these parts of the generator.

Solar Panel Input – A

The only wiring here is to connect the male 6-pin trailer plug to the solar panel harness. Connect the leads in the same configuration as the female socket, i.e., positive to the center pin and negative to the ground pin.

Solar Panel Input – B

This part of the circuit is already wired in.

Solar Panel Input – C

These leads are already connected to the charge controller and only need to be terminated and connected to the fuse box and negative bus bar. To do this, strip around ¼ inch of insulation off the ends of the battery output leads. Select two appropriate pre-insulated push-on spade terminals from the terminal kit (color-coded for ease of crimping). Use the correct color-coded notch on the crimping pliers to securely crimp the terminals onto the leads.

As indicated above, connect the positive lead to one of the spade connectors on the fuse box. Connect the negative lead to the negative bus bar.

External DC Charging Input – D

The battery maintainer DC leads are pre-connected to the unit and already have ring terminals fitted. You’ll have to cut these off and crimp a female spade terminal onto the positive lead. Connect the positive lead to an open spade terminal on the fuse box and the negative lead to the negative bus bar.

External AC Input – E

Plug the battery maintainer lead into the port plug extension to complete the external AC circuit.

This wraps up the battery charger connections.

Low Current DC Circuit

The low-current 12-volt multi-outlet pod consists of two outlets and an on/off switch. These outlets draw power from the fuse box, and the negative bus bar and the wiring routing are illustrated in the two diagrams below.

This outlet is wired using a daisy-chain wiring method that combines multiple elements using a single lead or wire that goes to the voltage source. This is how that works.

Wire a positive lead from a spade connector on the fuse box to one connection on the on/off switch for the multi-outlet pod. The other switch connection is daisy-chained to the two positive connections on the USB and cigarette lighter outlets.

Connecting the negative lead to the negative bus bar is similarly daisy-chained to the two negative connections of the pod outlets.

NOTE:

This component is supplied with a pre-terminated harness. You can use these, but they are very light gauge, so we suggest using your 14-gauge primary wire. This is probably a bit of an overkill, but it’s always better to upsize wiring.

AC Output Circuit

This part of the circuit consists of the 20 amp GFCI outlet, which is already wired and plugged into the inverter.

Inverter Remote On/Off Switch

The remote lead is already plugging into the RJ11 port on the inverter.

The last step in the wiring process is to re-connect the fuse box, and the negative bus bar leads to the battery and double-check that all other connections are tight and secure.

That completes the hard-point wiring of your DIY solar generator and just about wraps up the build as a whole. All that now remains is to neaten up the wiring and test the generator.

Testing the Generator

Before you finalize the wiring routing, test all the generator functions. Ideally, you should wheel the generator out into the sun to do this. However, it doesn’t necessarily need solar energy; you can also do it indoors with an artificial light source. At this point, the battery is connecting, and all circuits are live.

Generally, the battery will also be fully charged or pretty close to full. You can use the digital display on the inverter to check this.

Test the Fuse Functions

Before you proceed, you’ll need to put appropriate fuses into the fuse box. With the battery connected and no fuses in the box, the 6 red-blown fuse indicators will be illuminated. Now you can insert fuses of the following ratings:

- Charge controller charging circuit – 40 amp

- Battery maintainer – 5 amp

- Low current 12-volt pod circuit – 30 amp

Test the Charging Functions

Plug the solar panels into the trailer socket and illuminate them. The charge controller display and status lights will indicate a healthy charge cycle.

Now remove the solar panels and plug an AC extension into the port socket. The battery maintainer should also indicate a good charge function.

Test the Low Current DC Circuit

Turn the pod switch on and check that the led voltage gauge indicates 12 volts. Plug a USB device like a phone charger into the USB port and check that it works OK. Then use an appliance or device with a cigarette lighter plug to test the last outlet.

Test the GFCI AC Circuit

Check that the GFCI sockets power indicator and reset lights are on. Then plug any 120-volt AC appliance into the socket and check that the outlet is working correctly.

Test the High Current DC Quick Connect Socket

You can check the socket using this method if you have a quick connect equipped extension with a suitable 12-volt test appliance. If not, you can simply use a multimeter to check for 12 volts on the socket.

Test the Inverter Remote Switch

Monitor the inverter’s LCD and operate the remote switch checking to turn the inverter off and on.

If all the DIY solar generator components are working OK, you can wrap up the build by cleaning up the wiring.

Final Wiring Routing

One of the best ways to finalize a wiring project like this is using self-adhesive zip-tie cradles. These allow for permanent secure wiring routing that is safe and looks really neat. There’s not a huge amount of wiring for this build, so getting it all neat is simple.

The choice of final routing will be personal, and you will end up securing the wiring in a way that suits you. However, we suggest routing the wiring along the bottom of the walls of the case with a minimum of wiring crossing the floor. Don’t hesitate to use plenty of zip-tie cradles — when it comes to this sort of job, the more, the merrier.

And What Will This Solar Generator Kit Cost?

We have only calculated this DIY solar generator project cost on the major components, cases, and consumables. The tools you have been omitting because most items will already be on hand; if not, they’ll become part of your DIY inventory going forward. Here’s the big-picture cost breakdown.

- Case, parts, and components: $1.290.

- Consumables: $163

Total project cost: $1.453.00

Average compatible commercial product: $1.500 to $4,000.

The cost of this build may seem high when considering the price of some commercial products of similar inverter output ratings. However, there are some crucial points to consider when comparing clinical dollar and cents.

- Many commercial solar generators don’t include solar panels. If they do, they are the dinky fold-up types in our discussion of component description. We include a full-spec 100-watt panel in our build, and the rest of the components would support the expansion of your solar array.

- The choice of a good MPPT charge controller has been explained in the component choice section. You could save money on a cheaper PWM controller (as most commercial products do), but you’d sacrifice overall efficiency in the long run.

- Battery choice is another high-cost inclusion to this project. The Optima battery is not cheap, but it will add considerably to the overall efficiency of this project. We chose this battery because it enhances the overall design ethic of the project. Other batteries are cheaper but cannot deliver the long-term benefits of using the Bluetop battery.

Final Words

That’s it for your DIY solar generator project. You have proved that not only can you build your own custom DIY solar generator but probably build a better and more flexible product than a store-bought example. In addition, by using solar energy, you’re making our world a better place.

We hope that this DIY solar generator step-by-step build guide has made the process a little easier and that you’ll get years of good service out of your DIY solar generator.

If you’d like to leave feedback, questions, or suggestions regarding solar energy projects, please use the comments section below.