Why Your Rooftop Solar Installation Needs Waterproofing (Before It’s Too Late)

Updated:

Seal every penetration point where your solar mounting hardware breaks through the deck surface with marine-grade polyurethane caulk rated for continuous UV exposure and thermal cycling. I learned this the hard way after my first DIY installation when I assumed standard silicone would suffice—three months later, I discovered water pooling underneath the panels during a heavy rainstorm.

Apply a liquid-applied waterproof membrane across the entire deck surface before installing solar mounts, creating a continuous barrier that self-seals around fasteners. Products like modified polyurethane or rubberized asphalt roll on easily and cure within 24-48 hours, giving you a watertight foundation that moves with your deck’s natural expansion and contraction. This step costs roughly 3-5 dollars per square foot but prevents thousands in water damage repairs.

Install flashing boots around each mounting post using EPDM rubber sleeves designed for pipe penetrations—the same ones plumbers use for vent pipes. These flexible gaskets compress tightly around bolt shafts and accommodate slight movement without breaking the waterproof seal, even when your panels shift during wind events.

Test your waterproofing before energizing your system by running a garden hose over each mounting point for ten minutes while someone checks the ceiling below for moisture. This simple verification catches 90 percent of installation errors when fixes take minutes instead of hours of panel removal later.

Your rooftop deck serves double duty as both living space and power generator, but only if water stays where it belongs—outside and flowing away from your home.

The Hidden Risk: How Solar Installations Compromise Your Roof

Mounting Hardware: Your Roof’s Weakest Points

Here’s the uncomfortable truth I learned during my first rooftop solar installation: every single bolt, screw, and bracket you attach to your roof is essentially creating a tiny doorway for water. Even when installed perfectly, these penetrations are your deck’s most vulnerable spots.

Think about it this way. Your roof is designed as one continuous barrier against the elements. The moment you drill through that barrier to mount solar panels or deck supports, you’ve broken that protective seal. Water is incredibly persistent and will find even the smallest gap around mounting hardware, especially as materials expand and contract with temperature changes.

I remember watching rain pool around a mounting bracket during my second year with solar panels. Despite using high-quality sealant and following every installation guideline, the constant freeze-thaw cycles had created a microscopic gap. That’s when I realized that mounting hardware isn’t just about structural strength; it’s about long-term waterproofing strategy.

The challenge multiplies when you consider that a typical solar array might have 20 to 40 mounting points. Each one needs individual attention and ongoing maintenance to prevent water intrusion that could damage your roof deck, insulation, or even your home’s interior.

The Weight Factor Nobody Talks About

Here’s something I learned the hard way during my first rooftop solar project: solar panels are heavier than you think. A typical residential panel weighs between 40-50 pounds, and when you’ve got ten or twenty of them up there, you’re adding serious weight to your deck. This isn’t just a structural concern for your roof joists—it directly impacts your waterproofing.

When I installed my second array, I noticed something troubling after a heavy rain. Water was pooling in spots where it never had before. The combined weight of the panels and their mounting system had created slight depressions in my deck’s surface. These low spots became mini reservoirs, and standing water is waterproofing’s worst enemy. It finds every tiny weakness in your membrane and exploits it.

The weight also puts constant stress on your waterproofing layer. Think of it like sitting on a balloon—eventually, the pressure finds the weak points. This is especially critical on flat or low-slope decks where drainage already requires careful planning. Before you install panels, calculate your total system weight and consider whether your existing waterproofing membrane can handle that sustained load. Some membranes compress over time under heavy loads, creating those problematic pooling areas that lead to leaks and premature membrane failure.

Understanding Your Rooftop Deck: What You’re Working With

Flat Roof Membranes (TPO, EPDM, and Modified Bitumen)

When you’re planning a solar installation on a flat roof, understanding your existing membrane material is essential—it directly affects how you’ll mount panels and maintain that critical waterproof barrier.

TPO (Thermoplastic Polyolefin) is the white or light-gray membrane you’ll often see on commercial buildings. It’s heat-welded at the seams and generally solar-friendly because of its UV resistance. When I worked on my neighbor’s TPO roof, we discovered that most solar mounting systems designed for TPO use non-penetrating ballasted mounts, which sit on top without drilling holes—a huge win for waterproofing integrity.

EPDM (rubber roofing) is that black membrane that looks like a giant inner tube stretched across your roof. It’s durable and flexible, but here’s the catch: EPDM seams are glued or taped rather than heat-welded, making them slightly more vulnerable to solar installation activity. If you’re mounting panels on EPDM, take extra care around seam areas and consider using ballasted systems to avoid penetrations altogether.

Modified Bitumen looks like traditional tar-and-gravel roofing but with modern improvements. It’s typically torch-applied or self-adhering and creates multiple waterproof layers. The good news for solar enthusiasts is that modified bitumen handles foot traffic well during installation, though penetrations require careful flashing and sealant work to maintain that multi-layer protection.

Composite and Wood Decking

When I first planned my rooftop solar installation, I assumed my composite deck could handle anything—after all, it was marketed as weather-resistant. What I learned the hard way is that while composite and wood decking materials are great for ground-level patios, they behave differently when solar equipment enters the picture.

Composite decking typically consists of wood fibers mixed with plastic, creating a material that resists rot and insects. However, the mounting hardware for solar panels creates penetration points that can trap water between the composite boards and any waterproof membrane beneath. Wood decking faces similar challenges, with the added concern of natural expansion and contraction that can work mounting bolts loose over time.

The key consideration here is how water moves around and under your decking material. Solar panel frames and mounting rails can channel water in unexpected ways, pooling it against deck boards or finding gaps you didn’t know existed. I’ve found that using rubber gaskets at every penetration point and ensuring proper deck board spacing for drainage makes a significant difference.

If you’re installing panels on an existing deck, inspect the condition of boards carefully before drilling. Any soft spots or deterioration will only worsen once equipment is mounted overhead. Consider using flashing boots designed specifically for deck applications rather than standard roof penetrations.

Concrete and Pavers

Concrete and paver rooftop decks are incredibly common in urban settings, and I’ve worked with quite a few of these while helping friends set up their solar systems. These solid surfaces present unique waterproofing challenges because water doesn’t drain through them like it would with traditional decking materials. The key concern here is that any penetrations you make for mounting systems create potential pathways for water to seep underneath and eventually into your living space below.

For these surfaces, you’ll want to focus on surface-level waterproofing membranes applied before installation. Many DIYers successfully use liquid-applied waterproofing products that create a seamless barrier across the entire surface. Pay special attention to where pavers meet walls or railings, as these transition points are where I’ve seen the most issues develop over time.

If you’re installing solar panels on concrete, consider ballasted mounting systems that don’t require drilling into the surface at all. They use weighted trays to hold panels in place, which completely eliminates penetration concerns. Just make sure your roof can handle the additional weight before going this route.

The Right Time to Waterproof: Before, During, or After Solar Installation?

The Pre-Installation Assessment

Before you even think about mounting those solar panels, let’s talk about what’s already happening on your roof. I learned this the hard way when I rushed into my first installation—a small leak became a big problem once panels were in place. Trust me, fixing waterproofing issues after installation is ten times harder than addressing them upfront.

Start by checking your deck during and right after a rainstorm. Look for standing water or pooling areas—these are red flags. Water should drain completely within a few hours. Next, inspect the existing waterproof membrane if you have one. Are there cracks, bubbles, or peeling sections? Run your hand along seams and edges where the membrane meets walls or railings.

Head inside and examine the ceiling below your deck. Water stains, discoloration, or musty smells indicate active leaks that need immediate attention. Use a moisture meter if you have one—they’re about twenty bucks and incredibly useful for detecting hidden dampness.

Check all penetrations like vents, drains, and existing mounting hardware. These are common failure points. Finally, note your deck’s age and the last time waterproofing was applied. Most systems need renewal every 5-10 years.

Document everything with photos. This assessment becomes your roadmap for what needs fixing before those panels go up.

When to Call It: DIY vs. Professional Help

Here’s my honest take from years of rooftop projects: simple deck sealing with quality products is totally DIY-friendly if your roof is structurally sound and you’re comfortable working at heights. I’ve tackled several myself with great results. However, when solar panels enter the picture, things get trickier. If your waterproofing requires disconnecting solar panels, working around electrical conduits, or you discover structural damage like rotted decking or fascia boards, that’s when you need backup.

Cost-wise, DIY materials for a standard deck run $300-800, while professional installation starts around $2,000-5,000 depending on size and complexity. The middle ground? Handle the prep work yourself and bring in professional help for tricky areas around solar mounts and electrical penetrations.

Red flags that scream “call a pro” include water stains on interior ceilings, multiple failed DIY attempts, warranties you can’t risk voiding, or uncertainty about membrane compatibility with your solar mounting system. There’s zero shame in getting expert eyes on your project. I’ve called professionals three times when projects exceeded my skill level, and each time saved me from costly mistakes.

DIY Waterproofing Methods That Work With Solar Installations

Sealing Penetrations: The Critical First Defense

Here’s the thing about rooftop penetrations: they’re your deck’s most vulnerable spots, and I learned this the hard way during my first solar installation. Every bolt hole you drill is essentially inviting water to find its way through, so treating these points with serious care is absolutely essential.

Let’s start with the basics. Before you even think about mounting hardware, you need the right sealants. I recommend using a high-quality polyurethane or butyl rubber sealant specifically rated for roofing applications. These materials remain flexible through temperature changes, which is crucial since your deck expands and contracts with the seasons. Avoid cheap silicone sealants – they might save you a few dollars initially, but they’ll fail when you need them most.

When you’re ready to seal penetrations, apply a generous bead of sealant around each bolt hole before inserting the hardware. Think of it like creating a gasket. Once your mounting foot is positioned, add another ring of sealant around the perimeter where it meets the deck surface. Don’t skimp here – excess sealant can be trimmed away, but gaps cannot fix themselves.

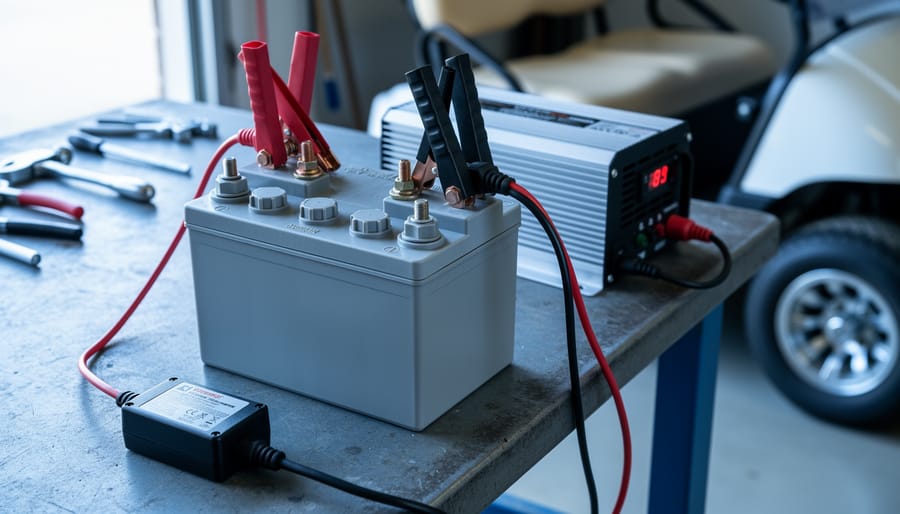

For larger penetrations, flashing boots are your best friend. These rubber or EPDM boots slide over mounting hardware and create a watertight seal that moves with your deck. I always apply sealant underneath the boot’s base flange before securing it with stainless steel screws. Then, run another bead along the top edge where the boot meets the mounting hardware.

Remember, water finds the smallest openings. Taking these extra sealing steps now prevents expensive repairs later.

Membrane Reinforcement Under and Around Panels

High-stress areas around solar panel mounting points need extra attention because these spots take a beating from both weight and movement. I learned this the hard way during my first installation when I thought the standard membrane would be enough—spoiler alert, it wasn’t.

Start by identifying where your panel mounts will sit. Before installing mounting hardware, apply an additional layer of waterproofing membrane patches around each planned penetration point. These reinforcement patches should extend at least 6 inches beyond where your mount will be. Think of it like putting an extra bandage under the main bandage—double protection where you need it most.

For the areas directly under panel arrays, consider using rubberized membrane products that can handle thermal cycling. Solar panels create shade but also reflect heat onto certain roof sections, causing expansion and contraction. A flexible membrane accommodates this movement without cracking.

Here’s a practical tip from the community: cut your reinforcement patches with rounded corners rather than sharp angles. Sharp corners can lift over time, but rounded edges stay sealed better.

Apply these patches when temperatures are between 50-80 degrees Fahrenheit for optimal adhesion. Press firmly from the center outward to eliminate air bubbles, and seal all edges with compatible waterproofing sealant. This layered approach creates a fortress of protection exactly where your roof needs it most.

Creating Drainage Pathways

Water needs somewhere to go, and if you don’t give it a clear path, it’ll find its own route, usually right into places you’d rather keep dry. When I installed my first rooftop solar array, I learned this lesson the hard way after a heavy rainstorm created a small pond around my mounting brackets. The water had nowhere to escape, and it just sat there, slowly working its way under the waterproof membrane I’d so carefully installed.

The solution is surprisingly straightforward: create intentional drainage pathways that guide water away from your solar equipment and toward your existing roof drains or gutters. Start by checking your deck’s natural slope using a simple level. Ideally, you want at least a quarter-inch drop for every foot of horizontal distance. If your deck is relatively flat, you can create gentle slopes using tapered insulation boards or sleepers during your installation process.

Pay special attention to areas directly beneath and around your solar panel mounting points. These spots are particularly vulnerable because hardware penetrations can create small dams that trap water. I always position my mounts to work with the water flow, not against it. Think of it like a stream flowing around rocks rather than trying to push through them.

Consider installing channel drains or creating small trenches filled with gravel between panel rows if you’re working with a large array. This gives water multiple escape routes and prevents the pooling that can eventually compromise even the best waterproofing job.

Materials and Tools: Your Waterproofing Shopping List

Sealants and Adhesives That Last

Choosing the right sealant can make or break your rooftop deck waterproofing, especially when you’re adding solar panels into the mix. I learned this the hard way when I used a bargain-bin sealant on my first installation—it cracked within six months.

Let’s talk about your main options. Polyurethane sealants are workhorses for solar installations. They create a flexible, durable bond that moves with your roof’s natural expansion and contraction. The downside? They’re sensitive to moisture during application, so you’ll need a perfectly dry surface and good weather. They also break down faster under intense UV exposure, which matters if your panels don’t cover the entire deck.

Silicone sealants are the low-maintenance champions. They handle UV rays beautifully and stay flexible for years, making them perfect around panel mounts. However, they’re slippery—paint won’t stick to them, and they can be messy to work with. You’ll also pay more upfront.

For areas with constant water exposure, consider hybrid polymer sealants. They combine polyurethane’s strength with silicone’s weather resistance. They’re pricier but offer the best of both worlds for critical waterproofing zones.

My honest recommendation? Use silicone around your panel mounts and hybrid polymer for deck seams. Save standard polyurethane for less critical areas where your budget needs stretching. Whatever you choose, don’t skimp on surface prep—even the best sealant fails on a dirty surface.

Flashing and Boots: Don’t Skimp Here

Here’s where I learned the hard way not to cut corners. When I installed my first set of solar panel mounting brackets, I used generic aluminum flashing from the hardware store. Within six months, I had water staining on my ceiling. Quality flashing and boots are your roof’s armor against leaks at every penetration point.

For lag bolt penetrations where your solar mounts attach, invest in EPDM rubber boots or specially designed flashing kits made for rooftop solar. These create a watertight seal around each mounting point. I now swear by products like Quick Mount PV flashings or similar solar-specific systems that integrate the mounting hardware with the waterproofing layer.

Don’t forget pipe boots for any vents or conduits running through your deck. Replace old, cracked boots before adding solar panels on top—trust me, fixing them later means removing panels. Look for high-grade EPDM or silicone boots rated for your climate’s temperature extremes. Spending an extra twenty dollars per boot now saves you thousands in water damage repairs down the road.

Charles’s Real-World Solar + Waterproofing Project Walkthrough

Let me share what happened when I decided to mount a small 800-watt solar array on my garage’s flat rooftop deck last spring. I learned some valuable lessons about waterproofing the hard way, and I want to save you from making the same mistakes I did.

I was so excited about getting those panels up that I rushed through the waterproofing prep. Big mistake. I figured the existing rolled rubber membrane was in decent shape, so I just cleaned the surface and started drilling mounting holes for my racking system. Within two months, I noticed a water stain on my garage ceiling. That sick feeling in your stomach when you realize you’ve created a problem? Yeah, I had that.

Here’s what went wrong: I didn’t properly inspect the existing membrane for small cracks and aging. Even though it looked fine on the surface, the material had become brittle after years of sun exposure. When I drilled through it for my L-foot mounts, I created pathways for water without adequate sealing underneath.

The fix required me to remove all four panels, which took an entire weekend. I learned that proper waterproofing means working in layers. First, I installed flashing boots around each penetration point. These are rubber or metal collars that create a secondary barrier around any hole you make. Then I applied a generous amount of roofing sealant specifically rated for the membrane material. Finally, I added a top coat of sealant after the mounts were secured.

One thing I wish I’d known from the start: ballasted systems exist for a reason. If your roof can handle the extra weight, mounting panels on weighted racks without any penetrations eliminates most waterproofing headaches. I ended up using a hybrid approach, with ballasted racks at the center and only four penetrating mounts at the corners for wind resistance.

The repair cost me about 200 dollars in additional materials and two full days of work. But here’s the silver lining: I now check those seal points every spring and fall, which takes maybe 20 minutes. I’ve also installed a small moisture sensor in the garage ceiling, which gives me peace of mind.

My biggest takeaway? Patience pays off. Spend an extra day doing proper waterproofing assessment and preparation before any drilling happens. Your future self will thank you when you’re enjoying clean solar energy instead of dealing with water damage repairs.

Maintaining Waterproof Integrity After Installation

Seasonal Inspection Checklist

Making seasonal checks part of your routine doesn’t have to be complicated. I learned this the hard way after skipping a fall inspection one year and discovering a small leak had been pooling under my array all winter. Now I follow a simple quarterly schedule that takes about 30 minutes each time.

Spring is when I check for winter damage, looking for cracks or separations around mounting points where freeze-thaw cycles can cause problems. Summer inspections focus on UV damage to exposed sealants and checking that expansion joints are still flexible. Fall is crucial for clearing debris that accumulated during warmer months and verifying drainage paths are clear before winter rains arrive. Winter checks are brief—mainly looking for standing water or ice dams that shouldn’t be there.

Each season, I walk the entire deck perimeter, inspect around every mounting foot, and run water tests on any questionable areas. This proactive approach ties directly into your broader solar panel maintenance schedule. Keep a simple notebook documenting what you find—patterns emerge over time that help you catch issues before they become expensive repairs.

Spotting Problems Before They Become Disasters

Before you even think about installing those solar panels, let’s talk about becoming a rooftop detective. I learned this the hard way when I missed a small crack during my first deck waterproofing project – three months later, I had a water stain on my ceiling that looked like a map of Florida.

Start with a visual walk-around after a rainstorm. Look for puddles that stick around longer than an hour or two – standing water is your deck’s way of waving a red flag. Check the perimeter edges where your deck meets walls or railings, since these transition points are prime spots for seal failure.

Now get hands-on. Run your fingers along any visible cracks or seams. If they feel soft, spongy, or if your fingernail easily digs into the material, that’s membrane degradation in action. Look underneath overhangs or roof edges for dark streaks or discoloration – water stains often appear where you least expect them.

Inside your home, scan ceilings directly below the deck for yellow-brown rings, bubbling paint, or that musty smell that hits you when you open a closet. These inside clues often show up before outside damage becomes obvious. The key is catching these signs early, especially before adding the weight and penetration points of a solar installation.

Common Mistakes (And How to Avoid Them)

I’ve seen plenty of enthusiastic DIYers rush into waterproofing their rooftop decks before installing solar panels, only to discover leaks months later. Let me share the most common pitfalls I’ve witnessed in our community, so you can skip the headaches.

The biggest mistake? Skipping surface preparation entirely. I remember Charles telling me about a member who applied waterproofing membrane directly over dirty, flaking paint. Within six months, water was pooling underneath. The fix required stripping everything down and starting over. Always clean thoroughly, remove loose material, and let surfaces dry completely before applying any waterproofing product. It’s tedious work, but spending an extra day on prep beats redoing the entire project.

Another frequent error is choosing the wrong product for your climate. I’ve watched folks in Arizona use membranes designed for mild climates, only to have them crack under intense UV exposure. Similarly, people in rainy regions sometimes pick products without adequate flexibility for temperature swings. Take time researching which waterproofing systems work best in your area. Your local solar community forum can be invaluable here.

Improper flashing around solar panel mounting points causes countless problems. Many DIYers don’t realize that every penetration through your waterproofing layer needs careful sealing. When Charles installed his first rooftop system, he admitted he initially underestimated how much detail work goes into each mounting bracket. Create a water-tight seal around every bolt, using appropriate flashing tape and sealant. Think of water like a determined detective—it will find any opening you leave.

Finally, the classic mistake: applying waterproofing in less-than-ideal weather conditions. Installing membrane during high humidity, extreme temperatures, or with rain in the forecast compromises adhesion. Check your product’s specifications for temperature ranges and humidity requirements. Patience pays off when you’re not dealing with premature failures. Plan your waterproofing project during a stable weather window, even if it means waiting a few extra days.

Here’s the thing I’ve learned after years of working with solar installations: waterproofing isn’t the tedious chore standing between you and clean energy. It’s actually one of the smartest investments you’ll make in your entire solar journey. When I started my first rooftop project, I’ll admit I saw waterproofing as just another item to check off the list. But watching friends deal with leak damage years later taught me that those few extra hours spent sealing properly save thousands in repairs and protect your solar investment for decades.

Think of waterproofing as the foundation of your solar success story. A properly sealed deck means your panels perform without interruption, your home stays protected, and you sleep soundly during storms knowing everything’s secure. That peace of mind? Absolutely worth it.

Don’t rush this stage. Take your time reviewing the techniques we’ve discussed, and please use our community forums to ask questions. There are no silly questions here, just folks helping each other build better systems. Whether you’re planning comprehensive solar projects or starting with a small deck installation, approach waterproofing with confidence and patience.

Before you head to the hardware store, check out our site calculators to properly size your project materials and estimate costs. You’ve got this, and we’re here to help every step of the way. Welcome to the solar community.