Your Kohler Generator Won’t Start? Here’s How I Fixed Mine (And You Can Too)

Updated:

**Check your fuel level and oil pressure first**—90% of Kohler generator failures trace back to these two simple issues. I learned this the hard way during a three-day power outage when my generator shut down unexpectedly, leaving my solar battery backup system without its safety net.

**Listen to your generator’s behavior**. A sputtering start usually means stale fuel or a clogged carburetor, while a complete no-start points to battery or ignition problems. Overheating shutdowns signal airflow blockages or low coolant levels. Each sound and symptom tells you exactly where to look.

**Test the basics systematically** before diving into complex repairs. Verify your battery holds 12.6 volts or higher, inspect spark plugs for corrosion or wear, and ensure all circuit breakers are properly set. These five-minute checks resolve most common problems without requiring a service call.

**Know your limits**. While many Kohler issues are DIY-friendly—changing filters, cleaning terminals, replacing worn belts—electrical panel problems and fuel system leaks demand professional expertise. For those of us relying on generators as backup for off-grid solar systems, understanding when to troubleshoot yourself versus calling a technician protects both your investment and your energy independence.

This guide walks you through systematic troubleshooting steps, starting with the quickest fixes and progressing to more involved diagnostics, so you can restore reliable backup power today.

Why Your Kohler Generator Matters (Especially for Solar DIYers)

I’ll never forget the sinking feeling I had when our backup Kohler generator failed during a cloudy week last winter. My solar panels were producing minimal power, my battery bank was depleting fast, and suddenly my “energy independent” setup felt anything but independent. That experience taught me something crucial: for solar DIYers, a reliable backup generator isn’t just nice to have—it’s essential insurance for your investment.

Here’s the reality most of us discover after going solar: renewable energy is incredible, but Mother Nature doesn’t always cooperate. Extended cloudy periods, unexpected equipment failures, or higher-than-planned energy usage can all drain your batteries faster than anticipated. That’s where your Kohler generator becomes the safety net that keeps your lights on and your food cold.

Why do so many solar enthusiasts choose Kohler? Simply put, they’re workhorses. These generators are engineered for reliability and longevity, which matters tremendously when you’re counting on backup power during critical moments. While researching solar vs gas generators, I learned that many off-gridders specifically select Kohler for their automatic transfer switches and quiet operation—features that integrate seamlessly with solar systems.

But here’s what really matters: proper maintenance prevents those heart-stopping failures. A well-maintained Kohler can last 20+ years, protecting your energy independence without breaking the bank. Neglect it, though, and you’re looking at repairs costing hundreds or thousands of dollars—money better spent on additional solar panels or battery capacity.

Understanding basic troubleshooting empowers you to catch small issues before they become expensive emergencies, keeping your entire energy system running smoothly when you need it most.

Quick Diagnostics: Is It Really Broken?

The 5-Minute Safety Check

Before you grab any tools, let’s talk about keeping yourself safe—because a working generator isn’t worth a trip to the emergency room! I learned this lesson early on when I nearly shocked myself rushing to fix a generator during a power outage. Trust me, these five minutes could save you from a world of hurt.

**First, shut off the fuel valve.** This prevents gas from flowing while you’re working and reduces fire risk. Let the engine cool for at least fifteen minutes if it’s been running—hot components can cause serious burns.

**Next, ensure proper ventilation.** Never work on a generator in an enclosed space. Carbon monoxide is invisible and deadly, so move your unit outdoors or to a well-ventilated area if it isn’t already there.

**Disconnect all electrical loads.** Unplug everything from the generator and switch it to the “off” position. If your generator powers your home’s electrical system, flip the transfer switch to isolate it completely. Proper generator grounding is essential for preventing electrical shock, so verify your grounding connection is intact before touching any electrical components.

Finally, remove the spark plug wire to prevent accidental starts while you’re troubleshooting. Keep a fire extinguisher nearby, just in case.

Listen to What Your Generator Is Telling You

Your generator is actually a pretty good communicator if you know how to listen. I learned this the hard way during a power outage last winter when my Kohler started making noises I’d never heard before. Instead of panicking, I grabbed my flashlight and really paid attention to what it was trying to tell me.

**Rapid clicking sounds** usually mean your battery is too weak to engage the starter motor. The solenoid is trying to connect, but there’s not enough juice to complete the circuit. Think of it like trying to start your car with a dead battery—same clicking, same problem. Check your battery connections first, then test the battery voltage.

**Grinding or screeching** typically indicates the starter gear isn’t meshing properly with the flywheel. This could mean a worn starter motor or debris preventing smooth engagement. It’s like gears grinding in a manual transmission when you miss the clutch.

**Complete silence** when you hit the start button often points to electrical issues—blown fuses, tripped circuit breakers, or faulty wiring connections. No sound means no power is reaching critical components.

**Weak cranking attempts**—that sluggish, labored turning sound—suggest either a failing battery that’s partially charged or excessive resistance in the engine itself. Cold weather can cause this temporarily, but persistent weak cranking needs investigation.

Each sound is your generator’s way of pointing you toward the problem. Learning this language means faster troubleshooting and less downtime when you need backup power most.

The Visual Inspection That Saves Hours

Before you dive into complex diagnostics, spend five minutes on a thorough visual inspection—it’s surprising how often this simple step reveals the culprit. I learned this the hard way when I once spent two hours troubleshooting my backup generator, only to discover a wire had vibrated loose during the last storm!

Start by checking for fuel or oil leaks around the engine, fuel lines, and tank connections. Even small puddles point to specific problems—fuel leaks often mean cracked lines or loose fittings, while oil leaks suggest gasket issues.

Next, examine all visible wiring connections. Look for corroded terminals (they’ll appear green or white and crusty), frayed wires, or loose connections at the battery, starter, and control panel. A single corroded connection can prevent your entire system from starting.

Check the air filter housing for debris or damage, and inspect belts for cracks or excessive wear. If you have an off-grid solar setup with generator backup, corrosion becomes especially important since these systems often sit idle for extended periods.

Finally, scan for obvious physical damage—dented fuel tanks, cracked hoses, or broken mounting brackets. These visual clues often lead you straight to the solution, saving hours of unnecessary testing.

The Most Common Kohler Generator Problems (And Their Fixes)

Dead Battery Blues

I learned this lesson the hard way during a camping trip when my Kohler generator refused to start after sitting unused for three months. The culprit? A completely dead battery. If your generator won’t turn over or you hear that telltale clicking sound, the battery is your first stop.

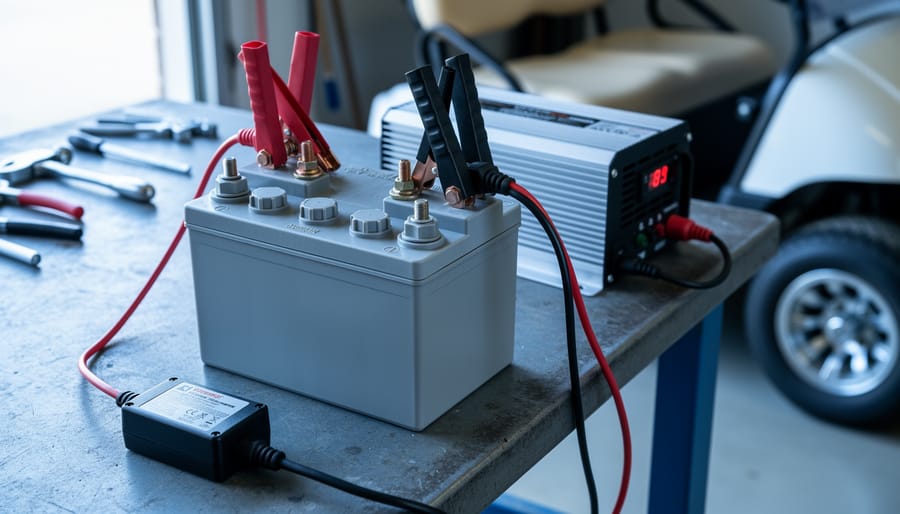

Start by testing the battery voltage with a multimeter—you’re looking for 12.6 volts or higher on a fully charged battery. Anything below 12.4 volts means it needs charging, and below 12 volts indicates a deeply discharged battery that may have suffered damage. Don’t have a multimeter? Most auto parts stores will test your battery for free.

To charge the battery, use a smart charger designed for deep-cycle batteries if possible. These prevent overcharging and extend battery life. Connect positive to positive (red to red) and negative to negative (black to black), then let it charge slowly overnight. Fast charging might seem convenient, but it can shorten your battery’s lifespan.

Here’s the thing about backup generators—they’re sitting idle most of the time, which is terrible for batteries. I now use a maintenance charger (also called a trickle charger or float charger) that keeps my battery at optimal charge without overcharging. It’s a simple plug-and-forget solution that’s saved me from multiple dead battery scenarios.

If your battery is more than three years old and won’t hold a charge, replacement is your best bet. When shopping for a new battery, write down your generator’s model number—battery size and terminal placement matter more than you’d think!

Fuel System Frustrations

Let me tell you about the time I spent two frustrating hours trying to figure out why my backup generator wouldn’t fire up during a storm—only to discover it was a fuel issue that took five minutes to fix once I knew what to look for. Fuel system problems are sneaky, but they’re also some of the most common and fixable issues you’ll encounter with your Kohler generator.

**Start with the Obvious: Check Your Fuel Quality**

Before diving into complicated diagnostics, pop open your fuel cap and take a look. Stale fuel is the number one culprit I’ve seen in generator problems. If your fuel has been sitting for more than three months, it’s probably gone bad. Gasoline breaks down over time, creating gummy deposits that clog everything up. Fresh fuel should smell like, well, gasoline—not like varnish or paint thinner. If it’s questionable, drain it out and start fresh. Trust me, it’s worth the small cost.

**Filter Check: Your First Line of Defense**

Your fuel filter is doing the heavy lifting to keep debris out of your engine. Locate it—usually between the tank and carburetor—and inspect it. A clogged filter looks dark or has visible particles. Replace it if there’s any doubt. These filters cost just a few dollars but can save you from expensive repairs down the road.

**Air in the Lines: The Invisible Problem**

Air bubbles in fuel lines prevent proper fuel delivery. Here’s how to check: disconnect the fuel line at the carburetor and place it in a container. Try starting the generator—you should see steady fuel flow. If it’s sputtering or inconsistent, you’ve got air intrusion. Check all connections for tightness and inspect lines for cracks.

**Fuel Pump Testing**

If fuel isn’t reaching the carburetor, your pump might be failing. With the line disconnected, you should hear clicking when attempting to start. No sound? The pump likely needs replacement. This is where many folks call in professional help, and there’s no shame in that—knowing when to seek expertise is part of being a smart DIYer.

Ignition and Spark Plug Issues

A generator that cranks but won’t start often points to spark plug troubles—something I learned the hard way during a weekend power outage at my cabin. Let me walk you through checking and fixing these issues so you can get your Kohler generator back up and running.

**Inspecting Your Spark Plugs**

Start by disconnecting the spark plug wire and removing the plug with a spark plug socket. A healthy spark plug should have a light tan or gray electrode. If you see heavy black carbon buildup, oil deposits, or a worn electrode, it’s time for replacement. I’ve found that checking spark plugs every 100 hours of operation prevents most ignition headaches.

**Testing for Spark**

Here’s a simple test: reconnect the plug wire to your removed spark plug, ground the plug’s threads against the engine block, and pull the starter cord. You should see a bright blue spark jump across the gap. No spark or a weak orange spark? Your ignition system needs attention.

**Proper Gap Specifications**

Most Kohler generators require a spark plug gap between 0.028 to 0.030 inches. Use a feeler gauge to check this—incorrect gaps cause misfiring or no start conditions. When installing a new plug (I recommend Champion or NGK brands), hand-tighten first, then give it an additional quarter-turn with your socket wrench.

**Troubleshooting the Ignition Coil**

If your spark plug looks good but you’re still not getting spark, the ignition coil might be faulty. Test it with a multimeter set to ohms. Check your owner’s manual for specific resistance values, but most Kohler coils should read between 2.5-5.0 ohms on the primary winding. Readings outside this range mean replacement is necessary—typically a straightforward bolt-on job that costs between $30-80.

Air Filter and Carburetor Cleaning

A dirty air filter is one of the most common culprits behind generator starting problems, and I learned this the hard way during a weekend camping trip when my Kohler generator refused to fire up. After some head-scratching, I popped open the air filter cover and found it completely clogged with dust and debris. Once I cleaned it, the generator roared back to life.

**Checking Your Air Filter**

Your air filter should be inspected every 25 hours of use or at least once per season. Remove the air filter cover—usually held by a single wing nut or clip—and pull out the foam or paper filter element. Hold it up to the light; if you can’t see through it, it needs attention.

For foam filters, wash them in warm, soapy water, rinse thoroughly, and let them air dry completely before reinstalling. Paper filters should be replaced rather than cleaned—they’re inexpensive and critical for engine health.

**Basic Carburetor Cleaning**

If your generator runs rough or won’t start even with a clean air filter, old fuel may have gummed up the carburetor. Start by draining the fuel bowl—there’s usually a small drain screw at the carburetor’s base. Fresh fuel residue should drain clear; thick, dark liquid indicates varnish buildup.

For minor issues, add a quality fuel stabilizer to fresh gas and let the generator run for 10 minutes. For stubborn problems, you may need to remove the carburetor and spray carburetor cleaner through the jets and passages. Always consult your owner’s manual for specific instructions, and remember that regular maintenance prevents these headaches entirely.

Oil Level and Sensor Problems

Your Kohler generator has a built-in safety feature that automatically shuts everything down when oil levels drop too low—think of it as your generator’s way of protecting itself from expensive internal damage. I learned this the hard way when my backup generator refused to start during a critical power outage, and it turned out I’d simply forgotten to check the oil after the last run.

Start by locating your dipstick (usually marked clearly on the engine). Pull it out, wipe it clean with a rag, reinsert it fully, then remove it again to get an accurate reading. The oil should reach the “full” mark. If it’s low, top it off with the manufacturer-recommended oil grade—check your owner’s manual for specifics.

Sometimes the problem isn’t actually low oil, but a faulty oil pressure sensor giving false readings. If you’ve confirmed the oil level is correct but your generator still won’t start, the sensor might be the culprit. You can test this by carefully disconnecting the sensor wire (with the generator off). If the unit starts without the sensor connected, you’ve found your problem. Replace the sensor—they’re inexpensive and easy to swap out.

Regular oil checks before each use prevent these frustrating situations, especially if you’re relying on your generator for backup power in an off-grid solar setup.

Control Panel and Electrical Gremlins

Your Kohler generator’s control panel is basically its brain, and when electrical gremlins strike, it can feel overwhelming. But here’s the good news—most control board issues are surprisingly fixable!

Start by checking your error codes. Your display panel speaks in numbers, and your owner’s manual translates them. Common codes like “1400” (low battery voltage) or “1501” (overspeed) point you directly to the problem. No power at all? Pop open the control panel cover and inspect the fuses—these little heroes sacrifice themselves to protect expensive components.

I remember Charles telling me about a customer who spent hours troubleshooting complex issues, only to discover a $2 fuse had blown. Always check the simple stuff first!

Before calling a pro, try resetting your generator. Disconnect the battery for 30 seconds—this clears temporary glitches. If error codes persist or you smell burning electronics, that’s your cue for professional help. Sometimes you might need to bypass the on/off switch temporarily for diagnostic purposes, but control board replacement typically requires expertise.

Document your error codes and troubleshooting steps—this information helps technicians (or future-you) solve problems faster while keeping your backup power reliable.

When Your Kohler Generator Runs But Won’t Produce Power

Testing the Circuit Breaker and Outlets

Before assuming your Kohler generator has a major malfunction, let’s verify your connection setup—I’ve seen countless DIYers (myself included) chase complicated fixes when the real culprit was something simple!

Start by testing your outlets directly. Plug a simple device like a lamp into different outlets on your generator. If the lamp works in some outlets but not others, you’ve likely got a tripped breaker or faulty outlet rather than a generator problem. Check your generator’s circuit breaker panel—reset any tripped breakers by switching them fully off, then back on.

Next, test with different appliances. Sometimes the issue isn’t the generator at all—it’s the device you’re trying to power. Also verify you’re using appropriate extension cords rated for outdoor use and your power requirements. Undersized cords can cause voltage drops that mimic generator problems.

If you’re connecting sensitive electronics, consider whether you need a surge protector for generators to prevent damage from power fluctuations.

Still having issues across all outlets with multiple devices? Now we can confidently move deeper into generator-specific troubleshooting, knowing your connections aren’t the problem.

Understanding AVR and Voltage Regulator Issues

Your Kohler generator’s Automatic Voltage Regulator (AVR) is like the steady hand that keeps your power flowing smoothly. Think of it as a traffic controller for electricity—it senses voltage fluctuations and makes constant adjustments to ensure your appliances get clean, consistent power at around 120 or 240 volts. When the AVR fails, you’ll notice lights flickering, voltage swinging wildly, or electronics shutting down unexpectedly.

I learned about AVR issues the hard way during a winter backup power situation. My generator was running, but the voltage meter was dancing between 90 and 150 volts—definitely not what you want powering sensitive equipment! Testing revealed a faulty AVR, which is actually more common than most folks realize.

**Testing Your AVR (DIY-Friendly Method):**

First, start your generator and let it warm up for five minutes. Using a multimeter set to AC voltage, check the output at the receptacle. You should see steady voltage within 5% of the rated output (115-125V for a 120V system). If the reading jumps around significantly or stays consistently high or low, your AVR might be the culprit.

Next, try adjusting the voltage adjustment screw on the AVR (consult your manual for location). Turn it slightly clockwise to increase voltage or counterclockwise to decrease. If small adjustments don’t stabilize the output, replacement is likely needed.

**When to Replace:**

AVRs typically fail after years of use or following power surges. Replacement units cost between $50-200 depending on your model, and installation is straightforward for anyone comfortable with basic electrical work. Always disconnect spark plug wires before working on electrical components—safety first!

Tools and Supplies Every Kohler Owner Should Have

Having the right tools and supplies on hand can mean the difference between a quick fix and hours of frustration—trust me, I learned this the hard way during a midnight generator failure at my off-grid cabin! Let’s talk about building a practical toolkit that won’t break the bank but will keep your Kohler generator running smoothly.

**Essential Diagnostic Tools**

Start with a quality digital multimeter (you can find reliable ones for $25-50). This single tool helps you check voltage output, test battery charge, and diagnose electrical issues. I also recommend keeping a spark plug tester ($10-15) and a basic compression tester ($30-40) in your arsenal. For those integrating generators with solar systems, these tools help maintain overall energy independence.

A flashlight or headlamp is non-negotiable—problems never seem to happen in broad daylight! Add a set of basic hand tools: screwdrivers (both flathead and Phillips), adjustable wrenches, socket sets, and needle-nose pliers. Most Kohler maintenance requires standard sizes, so a decent home tool kit usually covers you.

**Replacement Parts and Maintenance Supplies**

Keep spare spark plugs, air filters, and oil filters specific to your Kohler model. These wear items are your generator’s bread and butter. I always stock two of each because Murphy’s Law says you’ll need them at the worst possible time.

High-quality engine oil appropriate for your climate (check your owner’s manual) and fuel stabilizer are must-haves. For long-term storage or backup power scenarios, fuel stabilizer prevents carburetor gunk-up—a common culprit behind startup failures.

**Sourcing Genuine Parts**

While aftermarket parts tempt with lower prices, genuine Kohler parts from authorized dealers ensure reliability. Check KohlerPower.com for dealer locations, or reputable online retailers like Zoro and Shortridge Parts often stock authentic components. Local small-engine repair shops frequently carry Kohler parts and offer valuable troubleshooting advice—building relationships with these folks has saved me countless headaches over the years.

Preventive Maintenance That Actually Works

I learned the hard way that waiting until something breaks is the expensive approach to generator ownership. After my Kohler shut down during a critical backup situation about five years ago, I committed to a preventive maintenance routine that’s honestly saved me thousands in repair costs and countless headaches.

**My Monthly 15-Minute Check**

Every month, I do what I call my “coffee break inspection.” While my morning brew is cooling down, I walk out to the generator and run through a quick checklist. I check the oil level—it takes thirty seconds and catches problems before they become disasters. I look for any signs of leaks underneath, inspect the air filter for dirt buildup, and make sure nothing’s blocking the cooling vents. Rodents love warm generator enclosures, so I check for nests or chewed wires too.

The game-changer? I actually run my generator for 20 minutes every month, even when I don’t need to. This keeps the engine components lubricated, prevents fuel from gumming up the carburetor, and charges the battery. I can’t stress this enough—generators that sit unused for months are the ones that fail when you need them most. This simple habit has prevented more problems than any other maintenance task.

**Quarterly Deep Maintenance**

Every three months, I dedicate about an hour to more thorough care. I change the oil if I’ve been running the generator frequently, clean or replace the air filter, and inspect the spark plug. I also stabilize the fuel if I haven’t been using the generator regularly. Fuel degradation is the number one cause of starting problems I’ve seen in both traditional generators and solar generators for homes.

I keep a simple log in my phone noting what I did and when. It sounds tedious, but it takes literally two minutes and has helped me spot patterns—like noticing my oil was getting darker faster during summer months when I ran the generator more.

**The Battery Lesson**

Here’s something nobody told me initially: generator batteries need attention too. I check the battery terminals for corrosion monthly and keep them clean with a wire brush. I also invested in a simple battery tender for about thirty dollars that keeps the battery charged during long periods of non-use. This one small investment eliminated my “won’t start” problems completely.

When to Call a Professional (And How to Find a Good One)

I’ll be honest with you—I learned this lesson the hard way. A few years back, I attempted to adjust the voltage regulator on my backup generator without fully understanding the implications. Let’s just say Charles had to rescue me from a potentially dangerous situation, and the repair bill was significantly higher than if I’d called a pro from the start.

Some repairs are absolutely DIY-friendly, but others require professional expertise for safety and warranty reasons. Here’s when you should definitely call in a qualified technician:

**Warning Signs That Demand Professional Help:**

– Internal engine noises like knocking or grinding—these indicate serious mechanical issues

– Fuel leaks, especially near the engine or carburetor

– Electrical problems beyond simple wire connections, particularly involving the alternator or voltage regulator

– Control panel failures or error codes you can’t resolve through the manual

– Any issue involving natural gas lines (this is non-negotiable for safety)

– Persistent problems after you’ve tried basic troubleshooting

**Finding a Qualified Kohler Technician:**

Start with Kohler’s official dealer locator on their website—authorized service centers have factory training and genuine parts access. Don’t just Google “generator repair near me” without vetting the results.

**Essential Questions to Ask Before Hiring:**

– Are you Kohler-certified? (Ask for proof)

– What’s your experience with my specific model?

– Do you use genuine Kohler parts?

– What’s included in your diagnostic fee?

– Can you provide references from recent generator repairs?

– What’s your typical response time for emergencies?

Remember, a reliable backup power system is crucial for energy independence, especially if you’re running solar with battery storage. Sometimes paying for professional expertise protects your investment and keeps your family safe—that’s money well spent.

Here’s what I’ve learned after years of tinkering with backup power systems: most Kohler generator issues really are within reach of your DIY toolkit. You don’t need an engineering degree to get your generator humming again—just patience, a methodical approach, and willingness to start with the basics. Check that fuel, inspect those connections, and work through the simple stuff before assuming the worst.

I remember one particularly frustrating evening when my generator wouldn’t start during a power outage. After an hour of panic, I discovered the fuel shutoff valve was closed. Sometimes the simplest solutions are the right ones.

Whether you’re pairing your Kohler with one of the best solar generators or relying on it as your primary backup, keeping it maintained means true energy independence when you need it most. A reliable generator transforms your solar setup from a fair-weather friend into an all-weather powerhouse.

Now it’s your turn—what troubleshooting victories or head-scratching challenges have you encountered? Drop your experiences in the comments below. This community thrives when we share our knowledge, and your story might be exactly what helps the next person solve their generator puzzle.