How to Build a Solar-powered Electric Fence (With Diagrams)

Updated:

You can build a permanent DIY, 3-acre solar-powered electric fence can with basic technical skills in under a week. And depending on whether you opt for a custom or off-the-shelf solar fence charger, costs between $1,400 and $1, 800.

And it could be up and running in a couple of days or less, depending on the fence size.

Electric fencing is among the most effective and affordable ways of keeping livestock in and four, or two, legged critters out. And, in operation, they are really simple.

A mains power or solar-powered fence energizer sends regular, very high voltage pulses down the exposed wires of the fence. A series of earthed ground spikes are connected back to the charger to form a return path.

If an animal, or an unwary human, touches one of the exposed fence wires, the circuit is completed. The fence wire voltage then finds a path back to the charger through the unwitting victim to the ground circuit. This creates a rather forceful mental reminder to avoid the solar fence at all costs in the future.

And the great thing is unless bad practices are followed, electric fences are not dangerous to livestock or critters alike. The electric pulses generated by the fence charger are extremely high voltage, very low amperage, and of very short duration. So, although extremely unpleasant, they pose no electrocution risks at all.

Now, of all the options available, solar-powered electric fence installations are particularly attractive. They allow users to set up temporary pasturage in distant locations with no need for an electrical supply. So, let’s look at how to build a DIY solar-powered electric fence.

How to Build a Solar-powered Electric Fence Step-by-Step

Electric Fences in Theory

Electrified fencing has been around for a long time with the first mention of electrified wire barriers appearing in 1832. However, the general use of electric fences as livestock deterrents in agriculture emerged 100 years later in the 1930s. So, the theory is by no means new.

It is also by no means complex in theory although it is often governed by state or national legislation. An easy-to-understand example of how electric fences work is illustrated in the two graphics below.

You can liken solar electric fences to the very simple electric circuit illustrated in fig. 1.

Electron Flow Theory

In the (A) circuit, electrons flow freely from positive to negative through a load, in this case, a light bulb. For the circuit to work, it requires both an unbroken positive path and a negative return path.

The (B) circuit has an open switch included (1). With the switch open, the electrons still flow through the (3) portion of the circuit. However, the return path is broken, part (4) of the circuit is not energized and light cannot work.

In the last circuit (C), the switch is closed (2), the return path is restored, and the bulb lights up. This is the essential working theory behind the electric fence as illustrated in Fig. 2 below.

The Electric Fence in Operation

Fig. 2 illustrates a typical solar-powered electric fence installation. The positive output of a solar-powered fence energizer is connected to the strands of the fence. The negative, or ground, input is connected to one or more ground spikes driven into the soil.

When the fence is idle (A) the strands of the fence are energized by the solar-powered fence charger. However, they don’t have a return path to the chargers’ ground circuit. This is similar to the open switch part of Fig.1 where the fence strands are (3) and the ground circuit is (4).

The crow can safely sit on one of the fence strands and be unaffected by the charge. This is because the bird is not in contact with anything that can form a return path. Essentially, it isn’t even aware that it’s sitting on an energized fence wire.

However, the cow’s hooves are in contact with the ground and do form a return path. When it touches the fence the electrical pulse passes through its body, through the soil, and completes the circuit. Practically it simultaneously becomes the switch and the load (5). Of course, the result is predictably memorable and the solar-powered electric fence has done its job as a deterrent.

An Alternative Setup

The examples above use the common hot fence strand and soil-based ground return configuration. The other common setup for solar electric fences utilizes alternating hot and ground fence strands as illustrated in Fig. 3.

There are a couple of ways of setting up an alternating polarity solar-powered electric fence. Some installations use the setup above while others only include one ground return strand. Whichever way they are set up, including ground strands in the fence layout, increases the contact probability. This is particularly relevant where the prevailing soil conditions are very dry with a weak ground return capacity.

Setting Up a DIY Solar Electric Fence

In this example, we’ll detail how to build a solar-powered electric fence enclosing an area of 122, 500 ft². At just under 3 acres this would represent a fairly small installation for permanent perimeter fencing. It does, however, well demonstrate the materials used and the techniques for the installation process.

The basic layout is illustrated below in Fig. 4.

This fence is designed primarily as a psychological containment measure for cattle rather than an exclusion measure for outside animals. It will utilize a 12.5 gauge aluminum wire, 3 strand ground return configuration powered by a 3.1-joule fence charger. The chosen fence charger is battery powered, the battery being charged by a custom solar system.

Here is a broad overview of the components chosen and the reasoning behind the choices.

The Solar-powered Electric Fence Wire Choice

We have chosen to use a 12.5 gauge soft aluminum fence wire for this solar-powered electric fence. To justify this choice, here are some of the pros and cons of using aluminum fence wire in this gauge.

Pros

- Conducts electricity 4 times as well as steel wire (resistance of 10.3 ohms/Km).

- Is flexible and easy to twist and tie off by hand.

- Is one-third of the weight of steel wire.

- Lifetime guarantee against rust.

- Ideal for high power energizer long lead-outs.

- Can be easily re-spooled for reuse.

- Available in large spools (4,000 ft).

- Crimps well with less chance of kink breaks.

Cons

- More expensive initially than steel wire.

- Is susceptible to stretching due to its ductile nature.

- Does not have the same tensile strength as steel wire.

The Solar System Choice

There are two ways of approaching this part of the project. You could opt for an off-the-shelf solar fence charger, or build the system yourself from the ground up. We will detail the latter option here and include cost and performance comparisons between the two later.

The industry rule-of-thumb for solar panel choice for fence chargers is 10 watts for each joule the charger delivers. In our case, the chosen fence charger has a low setting of 1.1 joules and a high setting of 3.1 joules. Using the above rule would require us to use a solar panel of around 30 watts output.

The solar panel we have chosen is actually a very functional kit from Topsolar. The kit consists of a 30-watt solar panel and a 10 amp PWM charge controller. Also included is a set of cables and adjustable mounting brackets and hardware. Though the panel ships with mounting brackets we’ll use this separate $65 pole mount to attach it to the pole.

The Topsolar kit is readily available online and at $70 is good value for money considering what it includes. Also, taking into account the modest system demands, the PWM charge controller will perform well against its MPPT counterparts.

In fact, the entire system could be possibly used to run irrigation pumps and controllers in the paddock as well.

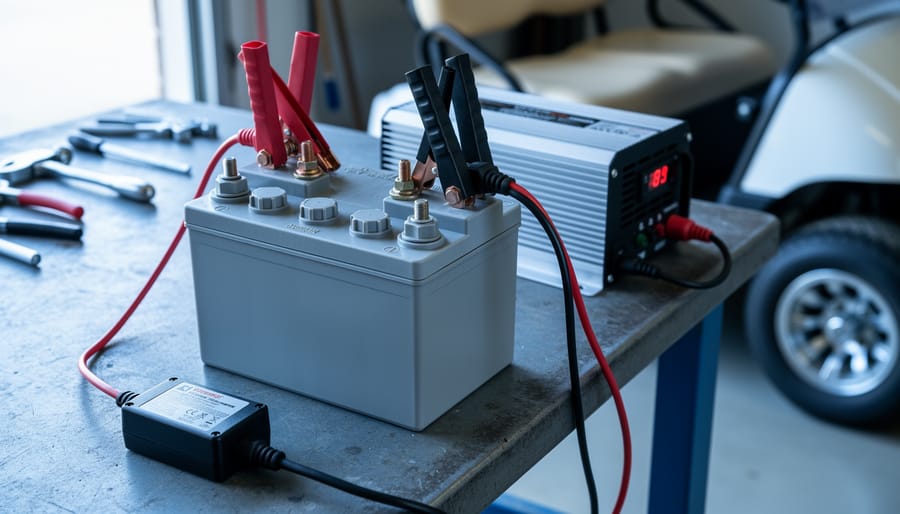

The Solar Battery Choice

The average 30-mile solar-powered fence charger would ideally be powered by a 70 Ah battery at the very minimum. And while LiPo batteries are the top-performing batteries, the demands of a fence charger system are negligible. So we have opted for a 12 volt, 100 Ah deep cycle marine-grade AGM battery kit from Renogy.

This battery choice may seem a little pricy at $287. However, Renogy is a respected brand it does include a sturdy, weatherproof battery box that will make the installation easier.

The Fence Charger Choice

Our choice of electric fence energizer is a 12-volt battery-powered model from Parmak, another well know and respected brand. The Mag12-UO is a low impedance, 30-mile electric fence energizer with some great features. And at around $100 it represents good value for money.

The Enclosure Choice

We could have mounted the solar electric fence components in a cheap toolbox but opted for a more formal approach. This approach is ultimately more rugged, convenient, and weatherproof, and is also easy to move if you ever have to. This in no way implies that a cheaper option would not be suitable, but we do feel that our choice is superior.

We have chosen to mount our solar-powered fence charger and charge controller in a 20″ x 16″ x 10″ electrical enclosure. Made of carbon steel with a lockable lid, removable back mounting plate, and cable access, this is an ideal option. It’s not cheap at $176 but is an excellent rugged, long-term solution.

Price Comparison

- Custom-built solar system – $698 ($540 to $600 if you use a cheaper battery)

- Parmak Mag 12 – SP integrated 30-mile solar fence charger – $320

Although the price is double that of an off-the-shelf model, the benefits of a custom solar system are considerable. The components are all far better quality and the performance and longevity of a custom system are hard to beat.

Constructing the Solar Electric Fence Charger Station

The first order of business here is setting up the charger mounting post. Any sturdy 6 x 6″ wooden or steel post that’s securely planted will do the job. The post should be long enough to stand around 8 to ten feet above ground level. The post should ideally be placed as close to one corner of the intended fence line as possible.

It would be a good idea to mount all the components To the post in their correct positions before wiring anything. Fig. 5 below depicts a suggested layout of all the main components.

The mounting methods for the different components will depend on your specific choices of components and post type. However, here is a bullet list of considerations when mounting the components.

- The solar panel ships with brackets and hardware for a flat surface mount. A single-arm, adjustable panel mount would be appropriate here though. This one costs $50.

- The charger/controller enclosure can be mounted with any number of store-bought or homemade brackets. Even 2 lengths of standard DIN rail would work very well. You would have to mount the brackets to the post first before attaching the enclosure which could be tricky.

- The battery and box weigh almost 70 lbs so a sturdy shelf mount would be a good idea.

Mounting and Wiring the Fence Charger Components

Once the post is set up, you can start to assemble the solar system and fence charger. A suggested layout and internal wiring schematic are illustrated in Fig. 6 below. The complete wiring schematic is illustrated in Fig. 7.

The layout and wiring of these components are very simple. And fortunately, the configuration of most charge controllers and fence chargers are also similar. So it doesn’t really matter what your choice of components is.

The solar panel outputs are connected to the positive and negative solar ports on the controller. Just make sure you get the right leads connected to the correct controller ports. The same applies to the two leads from the controller to the battery. The Topsolar kit does include battery leads but you may have to make your own solar wire if they’re too short.

In fact, you’ll probably have to splice extensions into most of the links that run between the main components. Just ensure that joints are well made and insulated. A tip here is that a well soldered joint insulated with heat shrink tubing is hard to beat. You can now wire all of the components together except the links between the charger and the fence.

Laying Out the Fence

We will assume that the perimeter of the fence has already been mapped out. It’s a good idea to use a blaze of limewash to mark the positions of the four corner posts. These will be the first elements you’ll install.

Note: Electric fencing is not high tension physical barrier fencing. None of the strands will be under high tension. They should be tight enough to keep them straight without sagging and to resist moderate pressure but not singing taught. For this reason, it is seldom necessary to brace corner posts on short electric fencing runs. Particularly with only 3 strands, such is the case with this solar electric fence.

Setting Your Corner and Gate Posts

The ideal corner post is a well-seasoned wood post that is around double the length of the highest fence strand. In our case, the highest strand is approximately 40″ of the ground. So an 80-inch post (6½ ft) would be perfect. For a fence of this type 6″ posts are fine.

A suggested corner post-installation is illustrated in Fig. 8 below. Please note the diagram is not to scale.

This corner post installation method involves digging a cone-shaped setting hole with its base at the bottom. It should be around 4 times as wide as the post and 6″ deeper than its underground length. This may seem strange, but the principle centers around 2 sound, basic mechanical principles.

Firstly, the cone-shaped plug places an excess of mass right at the base of the assembly. This will make the post less likely to succumb to cantilever forces exerted by the fence strands. In other words, it will be harder to pull out of the ground.

The second reason revolves around winter soil freezing. Water expands by 11 % when it freezes. If water seeps in around the plug it tends to pool around its base. During winter, if the water freezes, it expands and tends to push the entire pole out of the ground. A cone-shaped plug resists those forces better than a straight-walled plug.

The raised mound of concrete above the surface of the ground also serves a purpose. This will shed rainwater and prevent pooling around the exposed pole base thereby reducing the risk of the wood rotting. Repeat this process with the remaining 3 corner posts before we move on to the gate installation.

Important Note:

Try to ensure that all your posts are as close to level as possible when setting them. Most importantly try to get them set the same length above ground or as close as is possible. This will make running your fence strands straight a lot easier later.

Setting the Gate Posts

The last step in the corner/gate post setting exercise is getting the 2 gate posts set. Ideally, the gate should be placed close to the charger location as illustrated in Fig. 4. However, the placement would depend on your specific needs.

In either case, plan your gate carefully. Consider what the access and egress requirements would be. In other words what types of vehicles, if any, would use the gate. In addition, in what direction you would want to channel livestock out of the gate.

When you have chosen a gate width and location, plant 2 posts at that position using the methods outlined above.

Setting the Electric Fence Up

A quick note before we start with this section of the process. You are not building a high-tech engineering marvel here. So laser accuracy is not necessary for a successful and functional outcome. What you are shooting for is general uniformity in strand tension and separation and an acceptable degree of strand leveling.

What You Will Need to Build a Solar-powered Electric Fence:

To get this process done smoothly you will need the following.

- 1 x 4,000′ roll of aluminum 12.5 gauge fence wire

- 1 x 1,000′ roll of aluminum 12.5 gauge fence wire

- 6 x 6′ galvanized ground rods with clamps

- 1 x simple cable roll caddy

- 20 x pully style corner post insulators

- 15 x Gallagher G64302 inline wire tensioners

- 30 x Split bolt wire connectors.

- A pair of heavy-duty diagonal side cutters.

- 4 x packs of 6′ powder-coated hammer in U fence posts

- 3 x packs of 25 U post insulators

- A battery drill with a bit suitable for 3/8 inch wood screws.

- 1 x pack of donut insulators

- 1 x pack of tube post insulators

- 2 x single pole electric fence isolator switches

- 1 x lightning arrestor

- A 36 0r 48″ spirit level

- A tape measure

- An electric fence tester

- A lumber crayon or carpenters pencil

- A fence post mallet or hammer

- A solar power meter (optional)

Installing the Corner Post Insulators

Installing the corner post insulators is the first step in getting the fence strung. Start at the corner post nearest to the fence charger and mark off a point approximately 20″ off the ground. Mark the point as close to the center of the post in line with the far corner as you can. Again, laser accuracy is not called for.

Now working your way up the post, mark two more positions 10″ apart. This should leave you with around 10″ of the post above the last mark. Now use the spirit level to make sure all your positions are level. You can now drill holes at those marked positions and screw in corner post insulators with the pulleys facing upwards. The result should look like (A) if Fig.9 below.

When you are done you can move on to the next corner post and repeat the process. Try to keep your measurements and insulator positions as consistent as possible throughout the process. The orientation of the two opposing posts’ insulators should look like (B) in Fig. 9.

Now you can repeat the process for the remaining 2 corner posts and the gate posts. The final installation and the insulator orientation will look like (C) in Fig. 9. Once this part of the job is complete you can move on to stringing the fence strands.

Running the Fence Strands

This is a fairly lengthy, repetitive part of the process and involves a lot of walking. Let’s look at a broad overview of one of the best ways of getting it done.

The spool of fence wire is set up on the cable roll dolly at the fence charger position. Then a length of wire is walked off the spool to the next post. Leave around 6 to 8 feet for slack at the post and walk back to the spool. Pull another length of slack off the roll and cut the wire.

Now take the free end of the wire and repeat the process twice. You’ll now have three equal lengths of wire on the ground between the first two posts. Now you can start tying off the strands. This is feasible with short runs of fencing because it’s relatively easy to make sure you don’t cross-string the strands.

You can either complete each strand in sequence or tie off off all three ends on one post first. This is the method we’ll use because it doesn’t involve as much walking back and forward.

Start by running the slack on the first strand around the bottom insulators pulley to form a loop. Then wrap the tag end tightly around the running line between 5 and 6 times. This is illustrated below in Fig. 10.

Aluminum fence wire is soft and is fairly easy on the hands when it comes to tying off. The screw-in insulators also make the job a lot easier because they don’t move like tethered bullnose types.

Cut the tag end off flush with the last wrap and repeat the process with the second and third strands. Before you move on to the second corner post, take the middle strand of wire and pull about 15 feet back towards you. This will help to identify each strand later.

Tying off the Second Corner Post

Before you sally off to the second post get all your supplies together. This will be the diagonal cutter, three in-line tensioners, and the tensioning handle. Now pick up the bottom strand and, letting it slide through your hand, walk down to the second post.

Just before you reach the second corner post you should notice the end of one wire a way back from the post. This will be the middle strand. When you reach the second corner post with the bottom strand in hand, you can tie it off.

Repeat the process you used on the first post by looping the wire around the bottom insulator pulley. Pull the wire tight enough to leave a moderate bow in the strand. The point at this stage is not to tension the wire but to secure it. And you’ll need the slack wire to install the tensioner and that will then be used to tension the strand.

You can now walk back and retrieve the middle wire and repeat the process for the remaining 2 strands.

Installing the Tensioners

When all three strands have been tied off you can walk back to the halfway mark of the fence run. Using the manufactures instructions install the tensioners on each of the 3 strands.

The Gallagher in-line tensioner is a great tool for tensioning short-run electric fence wires. It doesn’t require you to cut and crimp any of the strands and is easy to use. When the tensioners are installed, start with the bottom strand and tighten up the run until it is straight. Remember, you don’t need the wire to be guitar string taught. Repeat the process with the middle and top strands.

You have now successfully installed the first run of your solar power electric fence.

Installing the Second Run

Now it’s time to move all your gear and the wire spool down to the second corner post. Here you will repeat the procedure you followed with the first run. Pull of the individual strands of wire, cut them off with a little extra slack, and lay them on the ground. Now you can tie all the second post lines off in the same sequence as the first post.

Tying off the second run of fencing is almost identical to the first with only one difference. When tying off each strand you will leave a long tag end at the end of the wrap. This is illustrated in (A) of Fig. 11 below.

Pull the tag end across to the first run strand and hold it in place with a pair of pliers. Now make a second set of 5 to 6 wraps as illustrated in Fig. 11 (B). Although the two loops do make contact around the pulley, this extra step ensures good continuity between the different runs.

You can now repeat the entire process for all the second and third run fence strands. The same process will apply for the 2 shorter runs between posts 1 and 4 and the two gate posts. When wiring the run between the second gate post and corner post 1, repeat the tag-end wrap procedure. This ties the last short run to the first fence section.

Once all the runs have been strung and tensioned you can move on to installing the inline fence posts.

Installing the Inline Fence Support Posts

We will use 6 foot powder-coated, hammer-in posts with insulators to support the run strands between corner posts. The posts will be placed at intervals of approximately 58 feet along each run. This will see 6 sub-posts on each run which is little more than necessary but does more good than harm.

This is a fairly expensive option but certainly far better in the long run than flimsy, step-in posts. In addition, steel posts are generally a no-go for electric fence posts. However, these posts are powder-coated not painted, and are a lot more durable.

The insulators will degrade over time but the fence line is unlikely to short out on the powder-coated posts. And insulators are affordable and quick to replace.

First, measure and mark the 6 support post positions between each corner post. Now hammer each support post into the ground until the brace plate is just below the soil surface. Make sure the U profile faces into the paddock interior.

Once the support posts are all installed you can walk the fence line and clip insulators onto the posts. Thread the fence strands through the insulator clips and you’re done. The insulators can be moved up and down on the post should you need to make adjustments.

Installing the Gate

There are many ways of installing gates on solar-powered electric fencing. We are going to use an example of tying an existing traditional tube frame gate into our electric fence. This essentially requires stringing one or more conductors across the gate frame and connecting them to the powered fence. These strands are insulated from the gate and connected to the fence with flexible insulated wire links.

The gate wiring layout is illustrated below in Fig. 12. NB: The illustration depicts the gate from inside the paddock with the solar fence energizer towards the left.

In reality, it is only necessary to have two strands on the gate, one hot and one ground. We’ve included a second hot strand here for illustrative purposes.

The gate wiring is mounted on stand-off donut insulators (1) and tube post insulators (2) as illustrated above. The method of making up the strands would be the same as the rest of the fence.

Please note. The donut insulators need to be installed with bolts long enough to give a 2 to 3-inch separation from the gate structure.

Connecting the Gate to the Fence

A length of 10 gauge insulated wire is spliced into the top hot strand of the fence (A) using an L clamp. That is connected to a blade-type isolator switch mounted on the fence post (B). A length of insulated wire is connected to the other side of the switch. This is and spliced to the top gate strand with another L clamp (C). An insulated jumper lead then joins the top and bottom hot strands at (D).

The ground is supplied via a lead spliced onto the fence ground strand (E) and the second gate strand (F). This would also be 10 AWG insulated wire and L clamps used for the splices.

Important Note: Make sure that the links between the isolator switch and the fence do not pinch or get caught in the gate when it opens. Also, ensure that gate stops are built-in so the gate can only open inwards towards the links.

Connecting the Fence Charger to the Fence Circuit

At this point, the solar electric fence installation is complete and the fence charger can be connected. The first order of business is to install the first 3 ground rods close to the charger and the first corner post. The ground spikes should be at least 6′ long and placed approximately 10′ apart.

Mark the rod positions out and drive them into the ground until there is around 3″ above ground. Then drive a fourth rod into the ground about 30 feet from the first group towards the second corner post.

The next step is to mount the lightning arrestor (B) and isolator switch (C) on the first corner post. These positions are shown in Fig. 13.

Once these components are mounted you can start the final wiring. Before you start the process ensure the fence charger battery leads are disconnected.

Connecting the Hot Circuit

First, connect an insulated 10 AWG lead to the positive terminal of the fence charger (A). Run this lead to the top lug of the lightning arrestor (B). Run a second, short link from the same arrestor lug to the bottom connector of the isolator switch (C).

Now run a 10 AWG insulated lead from the other side of the switch to the fence (D). Cut a jumper lead that’ll run from the top hot strand to the bottom one. Connect both insulated leads to the fence strands with L clamps. Now run a length of 10 AWG cable from the bottom lug of the arrestor to the fourth ground rod (E). When it is securely connected to the ground rod, the positive or hot part of the fence circuit is complete.

Connecting the Ground Circuit

The first step in the ground connections is running an insulated lead from the negative terminal of the fence charger (F). This lead connects to the first of the 3 ground circuit rods (G). Insert bridge leads from the first rod to each of the others making sure the first 2 clamps are tight.

Now run the final ground connection up to the middle strand of the fence from the third ground rod. Make sure the final ground rod clamp is tight. Then splice the other end of the ground lead to the middle fence strand with an L clamp (H).

This completes the ground circuit and the final wiring of the solar electric fence. You can then move on to testing the installation.

Testing the Fence Circuit

Before you connect the chargers battery terminals open both the main and gate power isolators. Now you can connect the charger to the battery and check that the voltage reading is at around 8,000 volts. Start off by closing the main isolator switch to put power on the fence to power the main circuit up.

Our Solar-powered Electric Fence Tester

We have chosen the Gallagher remote tester and fault finder as our diagnostic tool. It is not cheap but by far one of the most versatile and useful testers around. If you are going to be running electric fencing in the future it will be an excellent investment.

The tester has a metal pad that is simply held against a hot fence strand to show voltage, amperage, and the direction of any faults. Its main functions are illustrated in Fig. 14.

Start at the first corner post and place the test pad under the top fence strand. The amperage reading on a fence this short should be less than one Amp. The voltage reading should be around 7,500 volts (7.5 KV on the display) and there should be no error arrow. Repeat the process on the bottom fence strand.

Switch off the isolator switch and check again. If there are no readings then you are sure the isolator is working correctly. Switch the isolator on again and move to the first line post. Now repeat the testing process along the entire fence perimeter checking the lines at each line post. If the tester returns normal readings around the fence the installation is successful.

Testing the Gate Circuit

The last hot test for your new fence is the gate circuit. We have included an isolator on the gate circuit so it can be worked on without isolating the whole fence. At the moment the isolated is open so go ahead and close it. Now conduct the same tests on the 2 hot strands checking for correct operation.

If all tests are normal, congratulations. You have a properly installed electric fence and it’s working correctly.

Additional Tips

- Extra earthing. It may be a good idea to insert at least one extra ground rod in the middle of each run. Tether the rod to the fence ground return strand with a length of fence wire and an L clamp.

- Testing the earth strand continuity. If you disconnect the ground strand of the fence from the ground rods it can be made hot and tested. Use an insulated cable with crocodile clips on each end to link a hot strand with the ground strand. This makes your ground strand hot and allows you to test it with the fence tester. If it tests OK all around, the continuity is good. This is a more accurate test of ground return health than measuring resistance.

- Don’t ever electrify barbed wire fences or integrate electric fencing with them. This poses a serious entanglement and potential electrocution risk for animals.

In Conclusion

The solar electric fence is an excellent way of combining the benefits of solar power with those of an electric fence. This tutorial may raise some eyebrows regarding the overall cost of the outlined components but keep this in mind. It is purely an example of what can be done and what materials and techniques can be used.

There may be cheaper and simpler ways of enclosing 3 acres of pasture with a solar-powered electric fence. That said, none of the parts, materials, and techniques detailed here are gospel. The way you would approach a similar project would be strictly subject to your budget and time constraints.

Either way, we hope this guide has been informative. If you have any suggestions or comments, please post them below.